A Professional XLPE Insulated Power Cable Manufacturer in China

Being a professional XLPE Insulated power cable manfacturer over 20 years, we are able to prodivde you a wide range of power cable voltage level rated up to 500 kV, also included

- Cable Straight Joint

- Cable Termination Kit

- Pluggable Cable Connector

- Cable Link Box

- Other Cable accessories

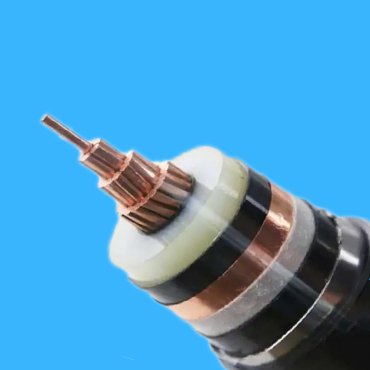

What is an XLPE Insulated Power Cable

An XLPE Insulated Power Cable means an electrical power cable using XLPE as an insulation material, armored or unarmored and sheathed by PVC or XLPE.

PowerTel & its associated factory have capacities to provide you a wide variety of XLPE insulated power cable, voltage rated from 1 to 500 kV, together with its cable accessories. Cold or Heat shrinkable terminal joint for medium voltage cable and porcelain or composite termination kit for high voltage cables.

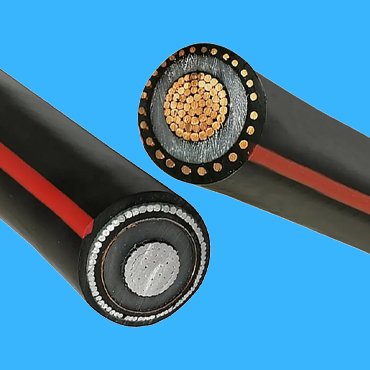

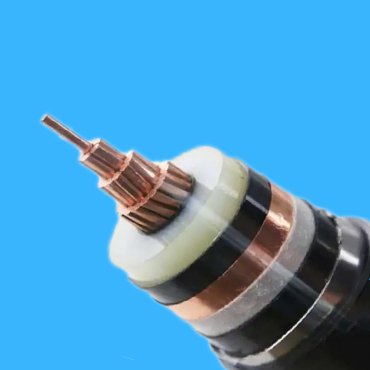

XLPE Insulated Power Cable--High Voltage

Stranded or Segment Al or Cu Consuctor

Conductor Shielded by a Non-metallic or a Semi-conducting Material

Conductor Size from 500 to 5000 kcmil, XLPE Insulated

Conductor range 750 to 6000 kcmil

XLPE Insulated

Triple Extrusion between conductor screen, insulation & insulation screen

XLPE Insulation

Insulation shielded by a Non-metallic or a Semi-conducting material

Metallic layer by Cu wires

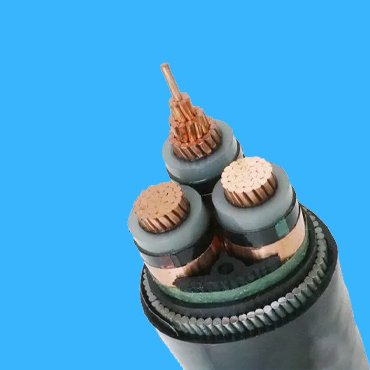

Stranded or Segment Al or Cu Conductor

XLPE Insulated

Outer sheathed by HDPE with an Al or Cu tape

Al or Cu Conductor from 1250 to 5000 kcmil

XLPE Insulated

Metallic layer by Cu wires

Stranded, Segment Al or Cu Conductor

Triple Extrusion for conductor screen,insulation & insulation screen

Sheathed by PE with an Al or Cu tape

Stranded Cu or Al Conductor to BS 6360

Insulated by XLPE

Conductor shielded by a non-metallic or a semi-conducting material

Referrting to IEC 60840

XLPE Insulation

Insulation shielded by a non-metallic or a semi-conducting material

Water Blocking tape used between Insulation screen & Metallic Cu wires

XLPE Insulated, Sheathed by PE with an Al tape

Solid,Stranded or Segment Conductor

Range from 300 to 2500 mm2

XLPE Insulated

Metallic shielded by Cu wires

XLPE Insulated & Sheathed by PE with an Al tape

Reffering to IEC 62067

XLPE Insulated & Shield by a Semi-conducting material

Triple Extrusion between conductor screen, Insulation & Insulation screen

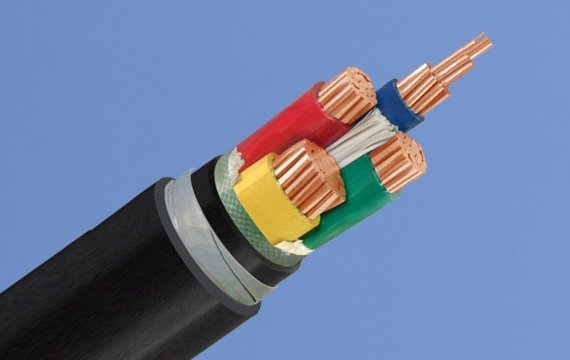

XLPE Insulated Power Cable--Medium Voltage

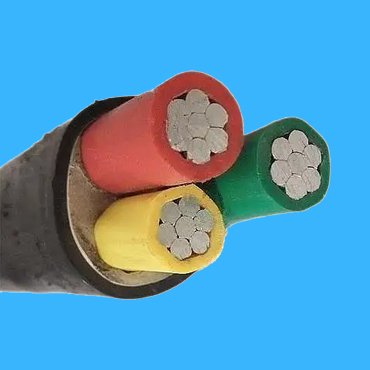

XLPE Insulated Power Cable--Low Voltage Level

Product Feature Box

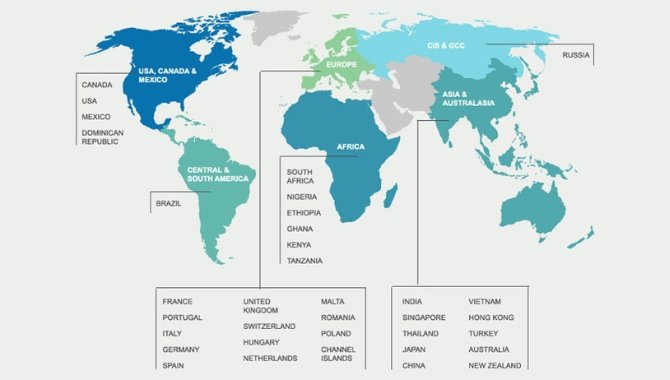

Worldwide Performance

Over 100 power utilities throughout the world used our XLPE Insulated Power Cable and They are all satisfied with our cable quality and after-sale technical support.

Custom Design of your XLPE Insulated Power Cables

No matter where your project is located in the coldest area or the hottest desert, our dedicated expert engineers can provide you a custom design for an XLPE Insulated power cable to fit your unique requirement.

Package Supply of Cables & its Accessories

Except for a medium or a high voltage XLPE insulated power cable, we can also provide you cable accessories as well, a seamless connection for your electrical system will be assured.

Cable Installation & On-site Technical Support

We are dedicated to offering the best quality technical support. Our Technical Consultants are amongst the most experienced people in the field and are available to come to your jobsite to address any technical queries you may have.

What is XLPE and its Advantages

XLPE is anabbreviated designation of cross linked polyethylene. Polyethylene has a linear molecular structure, while XLPE molecules bonded in a three dimensional network have strong resistance to deformation even at high temperature. Cross linked polyethylene is produced from polyethylene under high pressure with organic peroxides as additives. The application of heat and pressure is used to effect the

cross linking. This causes the individual molecular chains to link with one another which in turn causes the material to change from a thermoplastic to an elastic material.An important advantage of XLPE as insulation for medium and high voltage cables is their low dielectric loss.The dielectric loss factor is about one decimal power lower than that of paper insulated cables and about two decimal powers lower than that of PVC-insulated cables. Since the dielectric constant is also more favourable the mutual capacitance of XLPE insulated cables is also lower thus reducing the charging currents and earth-leakage currents in networks without the rigid star-point earthing.

Main Features of our XLPE Insulated Cables

Excellent Electrical and Physical Properties; A larger current carrying capability.

Easy Installation; Free from height limitation & Maintainance;

Related Product

What types of XLPE Insulated Power Cable

According to its voltage level, it would be low, medium, high voltage and even extra high voltage power cables.

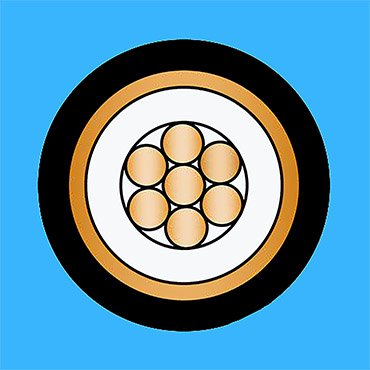

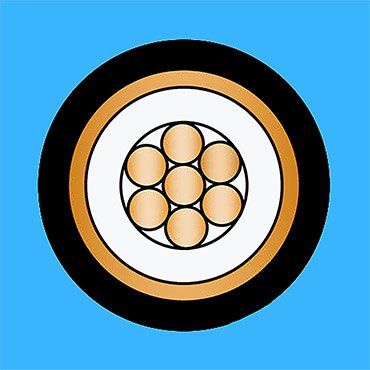

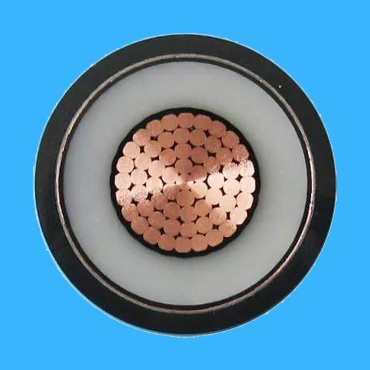

What components of an XLPE Insulated Power Cable

Conductor, Conductor Screen, XLPE insulation layer and Insulation Screen, AL or Cu wires & tape screened, Cu or Al Laminated tape and finally PE or PVC outer sheathed.

Manufacturing process for an XLPE insulated power cable

In the manufacture of medium and high voltage XLPE insulated cable our plant uses the latest technology available in the field by using an integrated high performance extrusion line which consists of a triple-layer extrusion and a water-free Completely Dry Curing Cooling(CDCC)gas-vulcanizing process.This type of extrusion line minimises the risk of introducing external contaminants an produces a high quality XLPE Insulated cable.

The conductor is paid off continuously through a metering capstan which is the line speed master point),a triple extruder,a vulcanizing tubean eccentricity monitoring unitand haul-off caterpillars, and finally taken up.

Using a group of three extruders,the triple crosshead allows simultaneous extrusion of the cable insulation and two semiconductor screens with a high degree of smoothness and no voids or introduction of extrernal contaminants.Precise and stable temperat

at the crosshead are achieved by using multiple zone temperature controls.

In the water-free CDCC gas-vulcanizing process,the triple-extruded cable core is cured in an inert pressurised gas tube and heated to the required temperature for material cross-linking.By varying the curing temperature and time, different cure percentages

be achieved as per customer requirements.The various functions of our intearated extrusion line such as line speed and curina tube temperatures synchronisation are

monitored and controlled via our automatic monitoring system.

Testing items for an XLPE Insulated Power Cable

Routine Test

These are tests to monitor overall cable quality and function. Tests listed here include high voltage tests, conductor resistance testinsulation resistance tests and voltage tests on protectives heath coverings.

Type Tests for an XLPE insulated power cable

These tests are used to calibrate and validate cable design type and they include bending teststhermal stability tests, impulse voltage tests,head distortion tests corona level tests and dielectric thermal resistance tests.

After Installation Tests for an XLPE Insulated Power cable

These tests are to determine and ensure that cables installed are in optimum operating conditions.Conductor resistance tests on the completed circuit verification tests of cross bonded systems and surge divertor tests are among the running lists of such critical test requirements.