Your Reliable ACSR Cable Manufacturer in China Since 1987

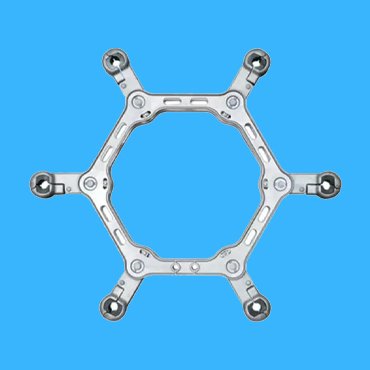

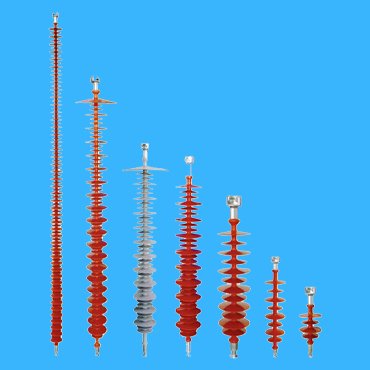

As a professional manufacturer in last three decades, we can supply a complete range of ACSR Cable and its associated hardware & fittings.

- ISO 9001 & 14001 Approved factory

- Monthly production capacity: 10,000 metric tons

- Over 35 years manufacturing experience, high quality guaranteed

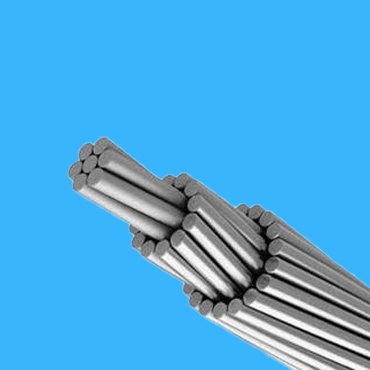

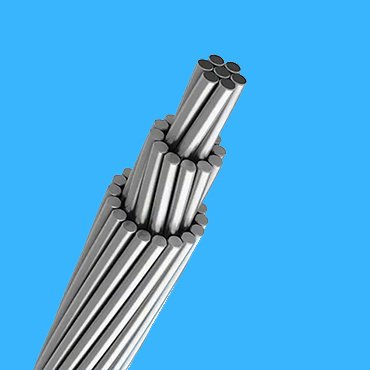

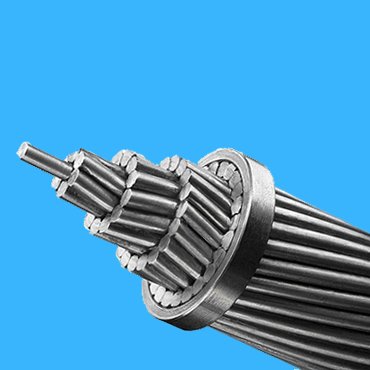

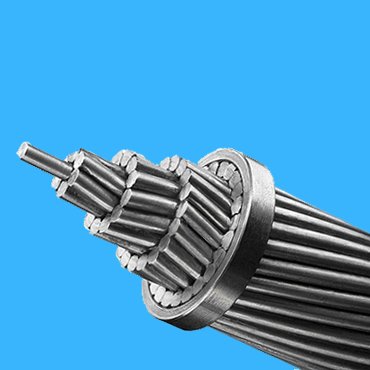

ACSR Cable

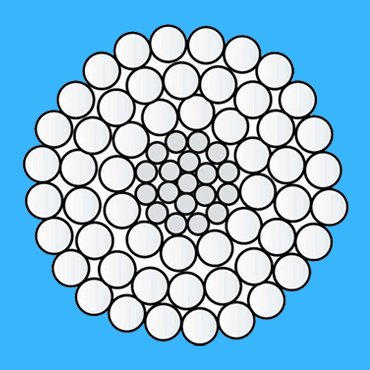

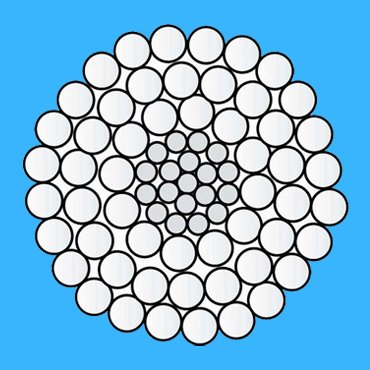

ACSR, Stranded Aluminum Conductor Reinforced by galvanized steel wires, The steel core is mainly used to increase the strength, and aluminum strand is mainly used to transmit electric energy, mainly installed on power transmission & distribution lines.

PowerTel & his associated factories have capacity to provide you a full range of ACSR Cable with different standards, like IEC 61089, BS 215-2, AS 3607 and ASTM etc. And also, its related hardware & fittings, like dead-end clamp, single or double suspension clamp, vibration dampers etc. Please consult it with our expertise to offer you a package supply for your projects.

ACSR Cable by ASTM Standard

ACSR Cable by IEC 61089 & EN 50182

ACSR Cable by AS 3607 & BS 215

Product Feature Box

Continous Casting & Rolling Technology

By using the most advanced continuous casting and rolling technology, we can directly produce aluminum rods, which helps us to reduce costs and maintain consistent quality of ACSR Cable.

Stranding Equipment for ACSR Cable

Maximum of 126 single Al & Steel wires can be supported at a time with this stranding equipment.

ACSR Cable Reels

Based on its reel length, we will select the right kind of reel to package your purchased ACSR Cable, 100% wooden reels or 100% steel reels, thus to guarantee that it will remain undamaged during the whole shipping process.

Related Product

Design, manufacturing, testing, inspection, packaging, and shipping for ACSR Cable.

All ACSR Cable will be designed by referring to related industry standards, like IEC, ASTM, AS & BS etc., which need to be approved by chief engineers before a real production.

Manufacturing for ACSR Cable

(1) During the whole manufacturing process for this ACSR Cable, we will strictly follow the all technical requirements in the technical specification, which was approved by end-user’ engineers. And moving smoothly step by step.

(2) Forming process for steel core & aluminum wire

In this process, we need to make sure there is no obvious gap or any loose strands for both steel core & aluminum wires. According to related standard, it is not allow to appear the bird cage occured before or after this ACSR cable stringed, which will produce some extra hear, further to cause a short circuit for a certain power transmission line.

(3) Precision machining from the very beginning to the end for fabricating this ACSR cable.

We understood, product quality is the only motivation for a fast developing company; We always take this precision machining policy as our first priority. We have rewarded a high reputation because of our highest quality ACSR cable. And we will insist to this quality policy all the time.

(4) Cleaning

The wire must not have excessive mold grease, metal powder, dust, or defects that are not commensurate with good industrial products. The final product should have no protrusions to limit the corona and radio interference generated during normal operation.

(5) Welding

All steel cores are not allowed to have joints, and the steel cores of the wires in a single contract should be produced by the same manufacturer.

(6) Strangulation

Twist evenly and tightly with galvanized steel wire as the center. The direction of each layer of wire twisting should be opposite, and the direction of the outermost layer of twisting should be in the right twisting direction (Z-twisting). The twisted steel core should be arranged naturally. After the steel core is cut, the steel wire should remain in place or be easily restored to its original position nearby. This requirement also applies to each layer of aluminum wire.

The twisting of wires should be carried out at once. During the twisting process, the steel core of the steel core aluminum stranded wire, the partially twisted wire, and the wire to be twisted should be left in the factory for a sufficient period of time to ensure that they are at the same temperature during the twisting process. During the stranding and storage process, the same program should be used to ensure that the wires to the same destination have the same stranding history as much as possible to achieve balance.

(7) Standard reel length for ACSR cable

Reel length on each reel can be on customer request, and not allow having any negative tolerance.

8) Warranty period for ACSR cable

The quality assurance period is 12 months after production or 24 months calculated from the date of the last batch of goods arriving at your job site.

Factory acceptance test for ACSR Cable

1) We shall notify the buyer by letter or email one month before the start of the factory inspection, and the buyer will send engineers to the factory to witness the goods experiment.

2) The representative of the buyer shall have the right to enter the factory and place where the products are manufactured from beginning to end, and we shall provide sufficient convenience for the representative to inspect the testing.

Testing items for a finished ACSR Cable

1) Size and ultimate strength test

2) Stress-strain curve testing

3) Creep test

4) Torque test

5) Wire fatigue test

6) Wire Corona Test

Routine test items for ACSR Cable

1) Appearance, dimensions, unit weight, and structure

2) Tensile strength test

Packaging and shipping mark for ACSR Cable

1) All packaging requirements should comply with the requirements of relevant standards, and have good protective measures such as moisture-proof, shockproof, rust proof, and anti-theft to ensure that the wires are safely transported to the site without being damaged due to the aforementioned reasons

2) The wire should use metal wire reels or steel wood structure wire reels to prevent damage to the wire during transportation, storage, and stringing operations on the construction site. The wire reel should be suitable for installing the wheel seat and can be used for a minimum control tension of approximately 5kN for wire laying.

3) Reel length and its reel size

Before the production of wires, the size of the wire reel used should be submitted to the buyer for clarification, and the wire reel cylinder should be covered with a moisture-proof protective cover.

4) Each reel can only have one complete wire. The minimum distance between the outermost conductor and the inner surface of the outer protective plate is 75m.

5) The two ends of each coil of wire should be reliably fixed, and the outer end of the wire should also be tightened to prevent the wire layer from loosening. The wires should be evenly and tightly wound on the coil, with each coil tightly attached to the previous coil, and the first and last coils of each layer should be tightly attached to the edge of the coil. When transferring from the lower layer to another layer upwards, there should be as few gaps as possible.

6) On the side of the wire reel, indelible ink should be used and the following prominent and easy to read signs should be printed using templates. Marking should be clear to ensure safe delivery to the destination and avoid the possibility of loss or packaging errors.

- Wire model and specifications

- Actual length of wire

- Gross and net weights

- Factory reel group number

- Contract number and consignee

- Arrow indicating scrolling direction

- Manufacturer name and its logo

- Production date

Shipping arrangement for ACSR Cable

(1) A group of four wire reels with a length difference of no more than 10m is required, and the wires in the same group must have the same stress-strain and creep characteristics.

(2) We shall take possible preventive measures to prevent damage to the wires during transportation. Vehicles loaded with materials should be cleaned and any unrelated items that may damage the materials should be removed.