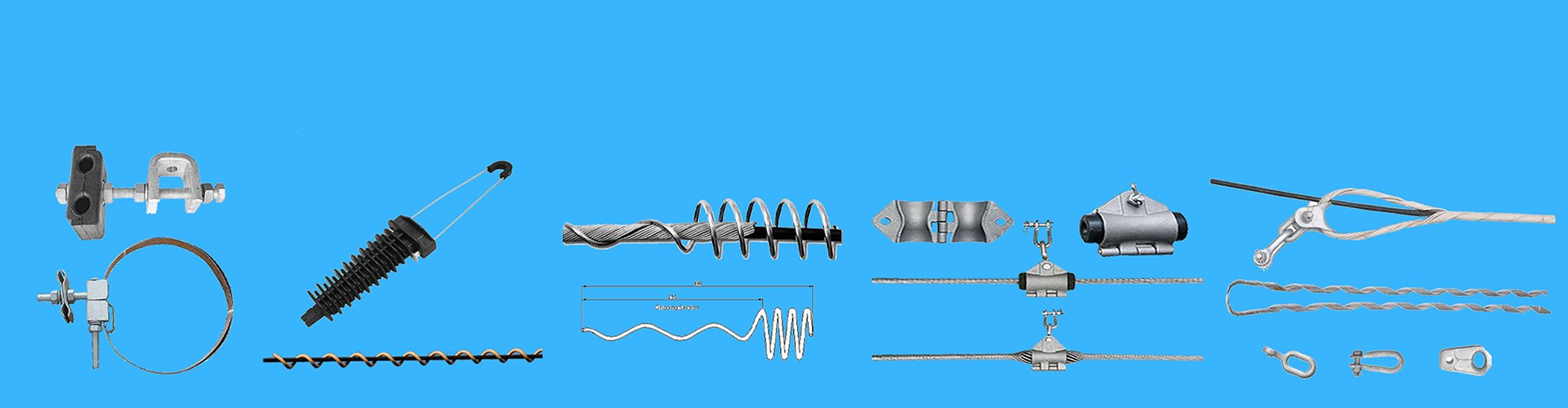

ADSS Cable Hardware

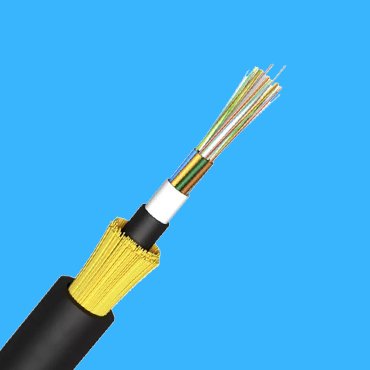

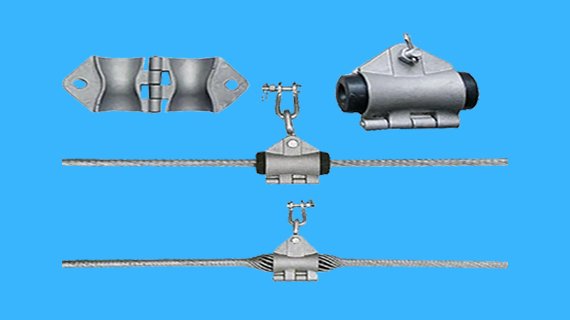

ADSS Cable, due to its own characteristics, it can withstand its own weight and external loads; When installed on power poles and towers, it is necessary to have some matching hardware and accessories to fix the cables on the poles and towers, like dead-end or tension clamp, single or double suspension clamp, downlead clamp, corona coil, spiral vibration damper and joint enclosure.

PowerTel & its associated factory can provide you a full range of ADSS Cable hardware for your installation of ADSS Cable and offer you some technical guide if it is necessary.

ADSS Cable Hardware

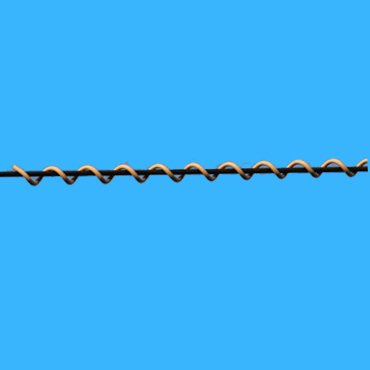

Anti-corona Ring for ADSS Cable

Anti-corona Ring is one of the important ADSS Cable harware, which mainly used on power transmission line above 220KV. Due to the fact that both the optical cable and the preformed fittings are located in a high electric field space, the end of the preformed fittings is susceptible to corona discharge. Posing a threat to the safe operation of ADSS cable. The anti corona ring can greatly improve the electric field state at the end of the fitting, reduce the electrical corrosion caused by corona on ADSS cable, and extend the service life of the ADSS cable.

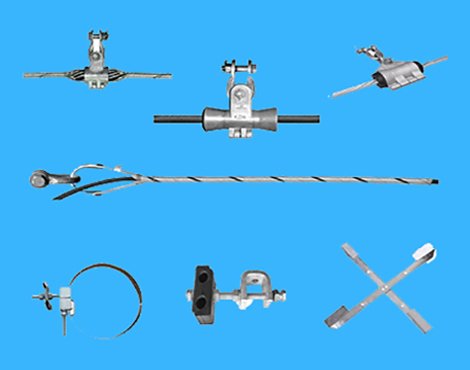

Preformed Tension Clamp

Preformed tension clamp is used for fixing and anchoring ADSS cable and is generally installed in terminal towers, tension towers, corner towers, and other locations. Each set of preformed wire tension clamp assembly includes: inner twisted wire, outer twisted wire, and pull ring. Features: The grip strength of the clamp can reach over 95% of the ultimate tensile strength (RTS) of the ADSS cable), without the impact of stress concentration and vibration stress.

Preformed Suspension Clamp

Preformed suspension clamp is mainly used for hanging ADSS cable. It is recommended to use an environment where the line corner is ≤ 30 degree. Features: 1. The reasonable distribution of extremely low static stress improves the bearing capacity of dynamic stress (such as vibration or galloping), and its grip strength can reach 10% to 20% of the ultimate tensile strength (RTS) of the ADSS cable. 2. There is no rigid contact with ADSS cable to minimize abrasion of the cable. 3. The excellent material makes the clamp have good elasticity and toughness, strong fatigue resistance and corrosion resistance, and long safe service life. 4. Not only effectively protects ADSS cable, but also its smooth contour greatly reduces corona discharge and electromagnetic losses.

Related Products

Installation Guide for ADSS Cable Hardware

- it is easy to cause damage to ADSS cable when installing the hardwares, especially for preformed one; it is necessary to use special installation hardware, while the use of screwdrivers and similar tools are prohibited.

- Due to the inevitable presence of dust and moisture on the surface of ADSS cable and in the surrounding air, there is a certain amount of electrical charge on its surface. Therefore, when installing these hardware on high voltage towers, the ADSS cable and its hardware should be grounded before being directly touched. When splicing fibers in ADSS cable , the cable located in the work area and between the static end connection fittings should be reliably grounded.

- Due to the long pre-twisted wires of ADSS cable hardware, there is a risk of electric shock due to slight carelessness during installation; We believe that, on the premise of ensuring that ADSS cable does not fall to the ground, the cable can be lowered by 3 to 5m in sequence, one by one, and dead-end and suspension clamp can be installed. After that, hanging the cable.