This post will include the folowing contetns

This post will include the folowing contetns

- What is an OPGW cable

- Key features of an OPGW cable

- What components are there in an OPGW cable

- Types of hardware for installing OPGW cable

- How to install opgw cable

- Why choose to buy our OPGW cable

- Conclusion

What is an OPGW Cable

It is short for Optical Ground Wire Cable, which has dual functions of ordinary overhead ground wire and fiber optic communication capability in power transmission & distribution system. It mainly used on newly-built overhead high-voltage power project of 35kV and above, and can also be used to replace existing ground wires of old overhead high-voltage transmission lines, increase optical communication , transmit short circuit currents, and provide lightning protection. It integrates ground wire and optical communication functions. The commonly used voltage levels are 110kv, 220kv, 500kv, 750kv and 1000 kV.

Key features of an OPGW cable

It can be used for both lightning protection and communication, without the need for an additional optical cable;

Optical fibers are located in the middle of the OPGW, and the outer layer is wrapped with aluminum clad steel or aluminum alloy wire for protection, which makes OPGW having a high reliability;

As OPGW is installed simultaneously with overhead conductor and traditioal earth wire on a transmission line, thus to save construction costs.

OPGW is installed on high towers of transmission lines, which is relatively safe and reliable, and is not easily stolen.

Small cable diameter and light in weight , low additional load on the tower.

The design of stainless steel pipes and cable cores is reasonable, and the excess length of optical fibers is accurate

Stainless steel tube protects optical fibers with high tensile strength.

Optical unit is located in the middle layer of the cable, which is resistant to twisting and has excellent lateral pressure performance

Different combinations of electrical wires, tailored design to fit your requirenent of various electrical and mechanical properties.

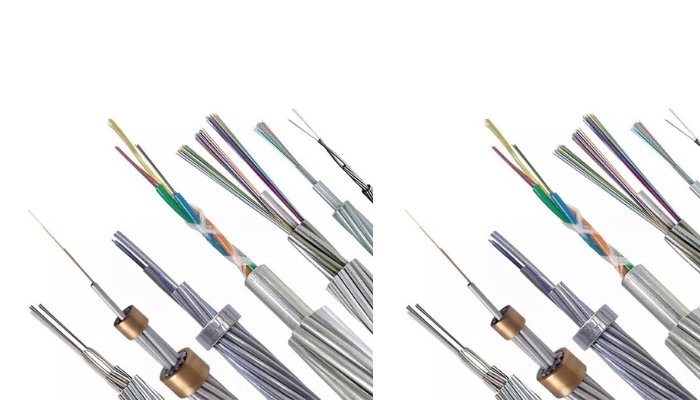

What components are there for an OPGW cable

- optical unit to house optical fibers, which is made of stainless steel tube, aluminum cladding stainless steel tube and aluminum tube; Fiber gel.

- Aluminum wire

- aluminum alloy wire

- aluminum cladding steel wire

Types of hardware for installing OPGW cable

Single or double dead-end clamp; single or double suspension clamp; vibration damper, downlead clamp and joint box etc.

How to install OPGW Cable

There are significant differences to install OPGW and traditional ground wires. This is because there is a fiber unit inside the OPGW, which may cause damage to the optical fibers and optical unit, due to excessive lateral pressure, torsional and impact force. Therefore, for installation workers, they should be taken seriously and paid attention to ensure the consutruction quality of OPGW cable.

1. Generally, installation of OPGW cable is to use tension stringing.

2. It is not allowed to damage the surface of aluminum clad steel due to prolonged contact and friction with the ground or other objects during stringing of the OPGW cable.

3. When using tension wire laying, it is necessary to use a traction machine and a tension machine. The tension machine can use double drum wheels (preferably) or single drum wheels, with a drum wheel diameter of at least 1m.

4. Material and diameter requirements for the groove bottom of the pay-off pulley: The groove bottom requires a layer of polyurethane rubber gasket, or nylon pulley. The bottom diameter of the wire pulley groove on the two tension towers behind the tension machine and in front of the traction machine should be greater than 40D (D referring to the cable diameter). It is recommended to use a single wheel aluminum or nylon pulley with an outer diameter of 600mm and an inner diameter of 560mm. The bottom diameter of the pulley groove on the remaining poles and towers in the middle should be greater than 30D (D referring to the cable diameter). It is recommended to use a single wheel aluminum or nylon pulley with an outer diameter of 508mm and an inner diameter of 408mm. Strictly prohibited to Use two or more small pulleys in combination.

5. Special construction tools required to install OPGW cable: The mesh sleeve connector and the application connector are special tools used to connect OPGW and traction steel wire rope. It is necessary to ensure the coordination between the mesh sleeve connector and the outer diameter of the optical cable and the tightness between the mesh sleeve and OPGW. Therefore, tie the front, middle, and rear parts of the mesh sleeve tightly with iron wire. When tightening the OPGW or installing hardware to pull the OPGW, it is necessary to use a bolt type wire clamp or pre twisted wire tightening fixture to form a circular slot hole to ensure that the OPGW is not subjected to local lateral pressure. If there is no bolt type wire clamp, tension resistant can also be used; A pair of tension clamps can be reused three times.

6. Before setting out and after tightening the wire, it is necessary to detect whether the optical fiber is damaged (testing for light attenuation) in order to check the quality of construction.

7. When setting out, each tower top and crossing point must be supervised by a dedicated person, in order to report and handle any wire clamping or other accidents in a timely manner.

8. When laying out, apply a tension of 20% -25% UTS, and the laying speed is 20-30 meters per minute.

9. Regarding on installation of OPGW hardware & fix the OPGW cable, it will be posted later.

Why choose to buy our OPGW cable

- over 20 years manufacturing experience and worldwide sale reference.

- type test report for OPGW & its hardware issued by some third parties.

- expert engineers are ready to provide you a tailored OPGW to fit your project

- Large production capacity assuring a fast delivery time

- package suply of materials, including opgw cable and its hardware etc

- On-site technical support for installing the OPGW cable

- Service for fiber splicing and final testing & commissioning

Conclusion

PowerTel & its factories are commited to providing you a package supply of materials for a power transmission or distribution line, including initial design of the line, selection of the products, OPGW cable, overhead conductor and its hardwares, power transformer, circuit breaker, electrical switchgear etc.