A Professional Drag Chain Cable Manufacturer in China since 2010

What is a Drag Chain Cable

Drag Chain Cable, installed in drag chain carrier, used in automated production processes for measuring, controlling, and regulating signals; It is more flexible and durable, suitable for use in frequently moving mechanical environments.

PowerTel and his factory have capacities to provide you a wide range of drag chain cable and drag chain carrier for your various applications.

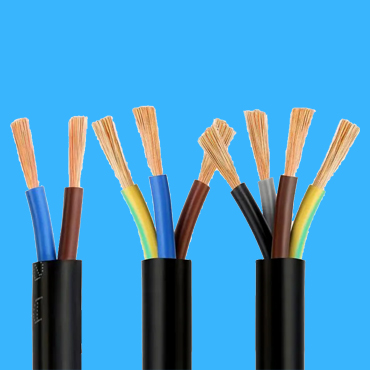

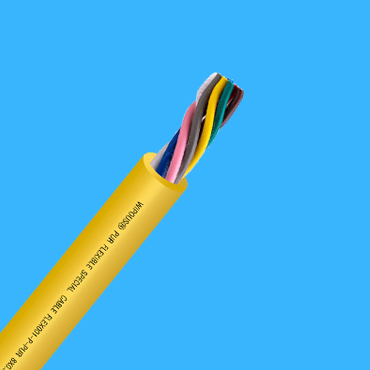

Medium Speed Flexible Drag Chain Cables

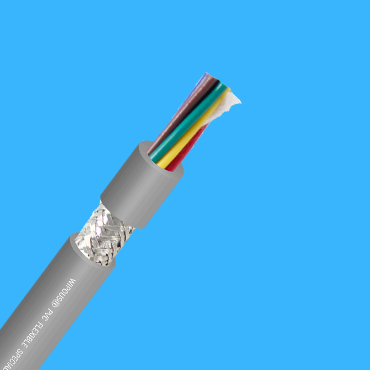

Suitable for electromagnetic compatibility EMC applications.

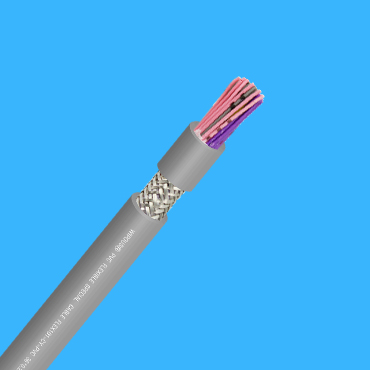

High Speed Flexible Drag Chain Cables

Resistant to bending over 10 million times; This need to be consulted with our engineers and make a custom design.

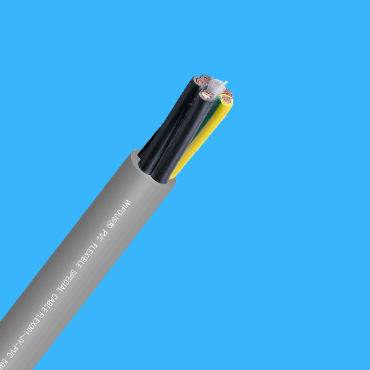

Special Drag Chain Cables

A data transmission system for automatic production processes with low temperature requirements, used for measuring, controlling, and regulating signals, is more flexible and durable, and suitable for use in frequently moving mechanical locations. Used in robot system such as body and arm systems

Oil resistance, comply with EN 60811-404

Cold resistance; Keep soft at low temperature, – 40 ℃.

Why choose us

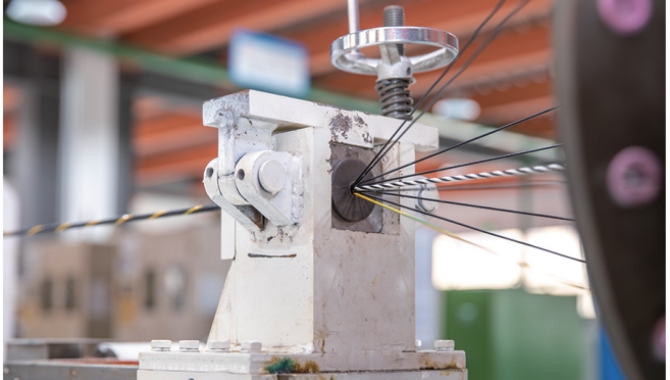

State-of-the-art manufacturing facility

State-of-the-art manufacturing facilities are the guaranttees of the highest quality of our drag chain cables.

All Drag Chain Cables are Fully Certificated

All our factories were certificated by ISO 9001 & 14001; Drag chain cables were certificated by UL & CSA/CUL; by VDE & TUV; by CE & ABS etc.

RoHS & REACH Compliance

All raw materials & finished drag chain cables are fully comply with requirements of RoHS & REACH, without any harmful effects for your health & environment.

Large Inventory for Drag Chain Cables

For medium speed drag chain cables, we did have a large inventory, thus assuring a fast delivery time; while for high speed drag chain cables need to have a custom design and fabrication.

Related Product

Some more information about drag chain cables

In situations where the equipment unit needs to move back and forth many times during their working time, in order to prevent cable entanglement, wearing, detachment, hanging, and scattering, the cable is often placed in the cable drag chain to form protection for the cable, and the cable can also move back and forth with the drag chain. This type of high flexibility specialized cable that can move back and forth with the drag chain but is not easily worn out is called a drag chain cable, which is also commonly referred to as a drag cable or tank chain cable.

Drag chain cables are mainly used in industrial electronic systems, automatic generation lines, warehousing equipment, robots, fire protection systems, cranes, CNC machine tools, and metallurgical industries.

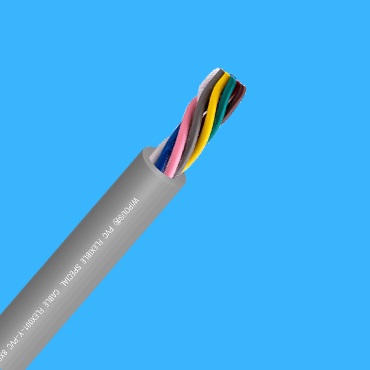

A drag chain cable consists of conductor, conductor insulation, inner sheath, shielding layer and outer sheath.

a drag chain cable should choose the most flexible conductor. Generally speaking, the thinner the conductor, the better the flexibility of the cable. However, if the conductor is too thin, it can cause cable entanglement. A series of long-term experiments have provided the optimal shielding combination of diameter, length, and pitch for a single wire, which has the best tensile strength; The insulation materials inside the cable must not stick to each other. And the insulation layer also needs to support each single strand of wire. Therefore, only PVC or TPE materials formed under high pressure can be used, which has proved its reliability in the application of millions of meters of cable in the drag chain; The shielding layer is tightly woven outside the inner sheath using an optimized weaving angle. Loose woven tape will reduce the EMC protection ability and the shielding layer will quickly be affected by shielding failure due to fracture. The tightly woven shielding layer also has the effect of resisting torsion; The outer sheath is made of different improved materials and has different functions, including UV resistance, low temperature resistance, oil resistance, and cost optimization. But all of these outer sheaths have one thing in common: high wear resistance and won’t stick anything. The outer sheath must be highly flexible but also have support function, and of course, it should be high-pressure formed.

Installation and precautions for a drag chain cable

1. The laying of drag chain cables should not be twisted, that is, the cable cannot be untied from one end of the cable drum or cable reel. Instead, the cable should be unfolded by rotating the drum or cable reel, and if necessary, the cable can be unfolded or suspended. The cable used for this purpose can only be directly obtained from the cable reel.

2. Attention must be paid to the minimum bending radius of the cable.

3. The cables must be laid loosely side by side in the drag chain, arranged as separately as possible, separated by spacers or inserted into the separation holes of the support brackets. The gap between the cables in the drag chain should be at least 10% of the cable diameter.

4. The cables in the drag chain must not come into contact or be trapped together.

5. Both points of the cable must be fixed, or at least at the moving end of the drag chain. The distance between the moving point of a general cable and the end of the drag chain should be 20-30 times the diameter of the cable.

6. Please ensure that the drag chain cable moves completely within the bending radius, i.e. it cannot be forced to move. In this way, the cables can move relative to each other or to the guide device. After a period of operation, it is best to check the position of the cables. This inspection must be carried out after the push pull movement.

7. If the drag chain breaks, the cable also needs to be replaced, as damage caused by excessive stretching cannot be avoided.