A Very Professional manufacturer of ACSR Wire in China since 1987

Over 35 years manufacturing experience, we are able to provide you a full range of ACSR Wire by referring to different international standards, such as ABNT NBR 7270, AS 3607, ASTM B 232, BS 215-2, CAN/CSA-C61089-11,DIN 48204, EN 50182, GOST839, IEC 61089, JIS C 3110, NF-C 34125 & SS 424 08 07 etc.

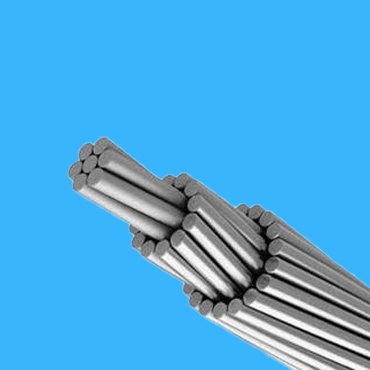

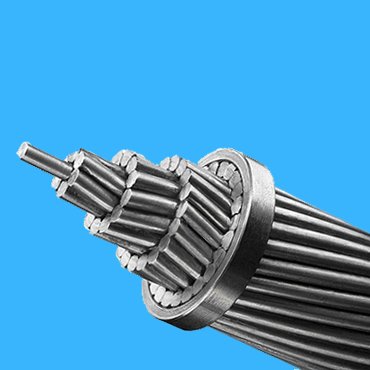

ACSR Wire

Multiple aluminum wires stranded outside the galvanized steel core wire, it is mainly used on power transmission & distribution lines.

It has the characteristics of simple structure, convenient erection & maintenance, low cost, & large transmission capacity, favorable for stringing across rivers and valleys and other special geographical conditions, good electrical conductivity, sufficient mechanical strength, large tensile strength, and adjustable distance between poles or towers. Therefore, it is widely used in overhead power transmission & distribution lines of various voltage levels. A proper type of ACSR wire or ACSR cable used on a power transmission line, it depends on its current carrying capacity,the number of circuits and voltage level etc. Please contact us for an optimal design.

ACSR Wire by ASTM Standard

ACSR Wire by IEC 61089 & EN 50182

ACSR Wire by AS 3607 & BS 215

Product Feature Box

Continous Casting & Rolling Technology

By adjusting the composition of trace elements (rare earth) in the aluminum liquid in the continuous casting and rolling process and controlling production process conditions, the strength and resistivity of the aluminum rod are ensured. In this process, the refining temperature and time of aluminum water are strictly controlled, slag removal and stirring are carried out to ensure the uniformity and stability of the chemical composition of the aluminum rod.

Manufacturing Process for ACSR Wire

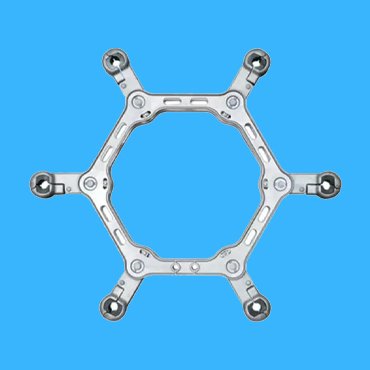

Equipped with high-speed 500 and 630 frame stranding machines with pre-twisting devices, with uniform and tight stranding technology; Equipped with wire breakage protection device to ensure high quality of our ACSR Wire.By adjusting the position of the guide wheel of the pre-twisting device, stress is eliminated to ensure the tightness of the ACSR wire and ensure that there is no obvious twisting or loose strands after cutting the wire.

Production Lines for ACSR Wire

Total six production lines for manufacturing ACSR Wire, allowing us to have an annual output of 60,000 metric tons ACSR Wire; this assure us to have a fast delivery time for your ordered ACSR wire and worldwide delivery,

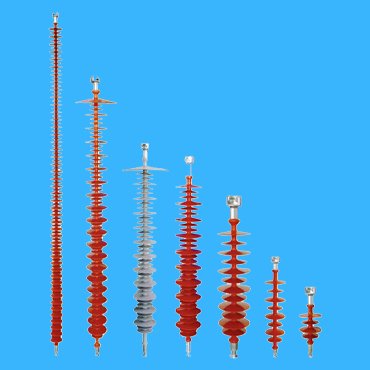

Related Product

What does ACSR stand for cable?

It stands for Aluminium Conductor Steel Reinforced, which is used on overhead power transmission & distribution lines, with strong tensile steel wire as the core of the wire and aluminum wire wrapped around it for current transmission.

What is the advantage & disadvantage of ACSR?

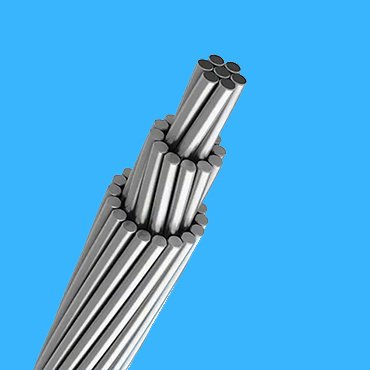

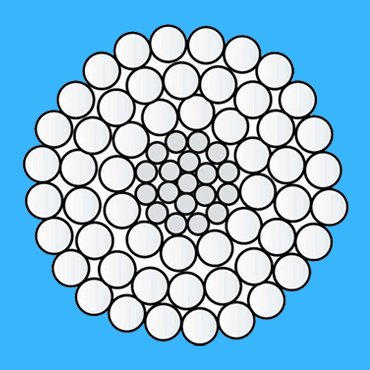

For an ACSR wire, it has 6/7/18/26/30/45/54 or 84 aluminum wires in the outer layer and has 1/7 or 19 different types of galvanized steel wires as a reinforced core; all these make the wire has an excellent conductivity, light weight, and strong tensile strength. Fortunately, although the conductivity of the steel wire is poor, due to the skin effect, most of the current passes through the outer layer of the cable. Therefore, it doesn’t matter if the conductivity of the steel core is poor; in other words, the higher the impedance of the inner layer, the better performance of an ACSR wire.

What is one advantage of using ACSR instead of copper conductors for a distribution line?

Copper has a high conductivity and a resistivity at 20 ℃ ρ 1.72 × 10-6 Ω· cm, resistivity of aluminum wire core at 20 ℃ 2.82 × 10-6 Ω· cm is approximately 1.68 times that of copper; When the current carrying capacity is the same, the cross-section of the aluminum wire core is about 1.5 times that of copper. The use of copper conductor has relatively low losses, and the mechanical properties of copper are better than that of aluminum. It has good ductility and is easy to process and install. The fatigue strength is about 1.7 times that of aluminum. However, the specific gravity of aluminum is small. When the resistance value is the same, the mass of aluminum wire cores is only half that of copper, and aluminum wires and cables are significantly lighter. What is more , the cost of ACSR wire is significantly lower than that of copper conductor and the cost is 3.8 times that of ACSR wire.

Meanwhile, the service life of ACSR wire is shorter than that of copper conductor, and the line loss caused by ACSR wire is greater than that of copper conductor. The cost of electrical loss is also considerable every year. In addition, due to the fact that the cross-section of aluminum core cables is 1.5 times that of copper core cables under the same current carrying capacity, the corresponding line protection cost and civil engineering cost will be increased as well.

Which is better ACSR or AAAC?

ACSR wire, due to excellent conductivity & low costs, it is widely used in power & transmission lines;

AAAC stands for All Aluminum Alloy Conductor, which has some good advantages of lower electrical loss, lighter in weight, and better sag characteristics. If used in a power & distribution line, it can reduce the height of electrical tower, increase the installation interval, save and reduce engineering investment, and also reduce tripping rate of the power line. Therefore, the use of all aluminum alloy conductors in power transmission & distribution lines is conducive to the safe, reliable, and economical implementation of the power grid, and is worth vigorously promoting and applying in urban and rural power grid renovation & upgrading, especially in some heavy-polluted areas, due to its excellent corrosion resistance.

What is the lifespan of ACSR wire?

The average service life of ACSR wire is expected to last 50 years in clean, moderate environmental conditions and 45 years in heavy polluted areas. .