A Best ADSS Fiber Optic Cable Manufacturer in China since 2010

As a professional manufacturer of ADSS Fiber optic cables over 20 years , we are able to provide you a full range of ADSS cables and their hardware and accessories.

Suitable for short, medium and long spans up to 1,500 meters or 5,000 feet

Suitable for light, moderate and high NESC conditions.

Number of fibers, up to 864

Technical support and custom designs for your special needs

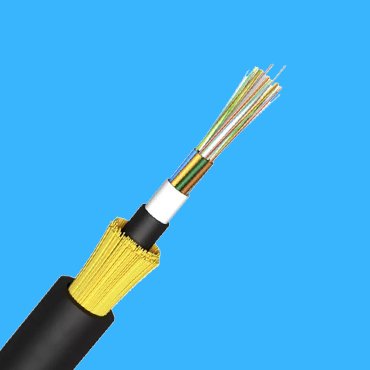

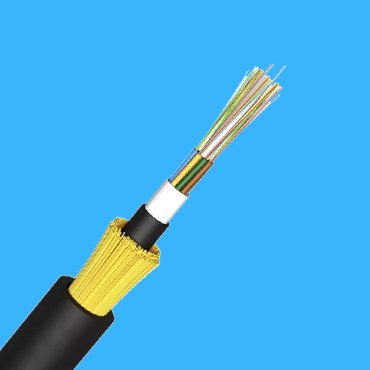

What is ADSS Fiber Optic Cable

It is one type of fiber optical cable, ADSS is short for All Dielectric Self Support, which is easily seen that there is not any metal material in the cable, and there is no need of any messenger wire to install this ADSS cable, and it is totally self supported. Electrical utilities need to make full use of their pole or tower resourse and intend to install this ADSS cable to rent to some telecom carriers or internet service companies; and also, we usually see some ADSS cable installed on power distribution lines in some rural areas for a telecommunication service for the people living in these areas.

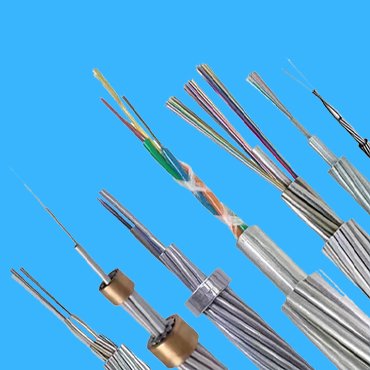

ADSS Fiber Optic Cable Categorized by its Structure

It has three main types; Central Tube ADSS Cable, Stranded Tubes in a Single Sheath, Stranded Tubes in Double Sheath. Fiber counts up to 864 fibers, Our expert engineers can offer you a tailored design on your technical info, such as voltage level of a power transmission line, Span length between towers or poles etc.

ADSS Fiber Optic Cable Categorized by NESC Conditions

It is GOOD for Light,Medium and Heavy NESC conditins, Fiber counts up to 864 fibers.

Product Feature Box

The State-of-the-art Production Lines

ADSS cables support up to 864 fibers and micromodule or airblown fiber cables support 1,728 fibers. Total 10 productions lines, allowing us to have a prompt delivery time for your ADSS Cable.

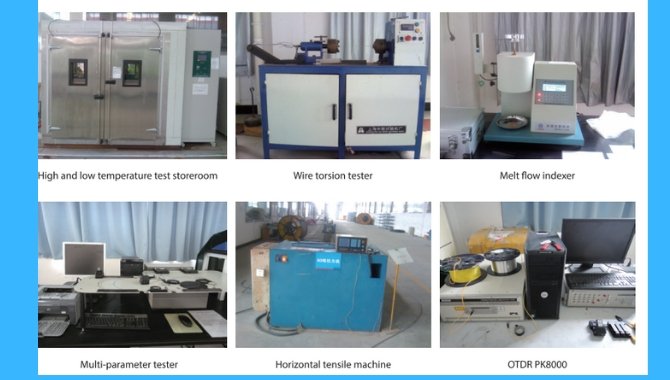

Well-equipped Testing facilities for ADSS Cable

Our well-equipped testing facilities are a further guarantte of high quality ADSS Cable, and support the development and research of new ADSS Cable.

Custom Designs available for your ADSS Cable

Please check it our engineers. they will make a specific design of this ADSS cables to fit your project, based on technical information you provided, such as the transmission or distribution line span length, voltage level etc.

Related Product

Why choose our ADSS cable

- Highest quality product

As a leading manufacturer of this ADSS cable in China, we have over 20 years manufacturing experience for this product; and we take the product quality as our life, and sold this ADSS cable to over 100 countries around the world.

- Fast delivery time;

Drawing on our large production capacity, we are able to make 100 km ADSS cable in 10 days after you approved the manufacturing drawings.

- Package supply of materials

Based on our complete product chain, except this ADSS cable, we can also provide a full sets of cable accessories and help you to install the cable on poles or towers properly, thus will save your time to talk with other suppliers and save your shipping cost at same time.