We all know that electrical busway was initially developed by some companies in United States and officially put into practical application in Japan in the 1950s.

Due to its high current carrying capacity, flexibility, safety, energy efficiency, and beautiful appearance, now it is an ideal choice for modern architecture and industrial & commercial projects, including large industrial plants, high-rise buildings, schools & hospitals, data centers, railway transition system, etc.,

At present, electrical busway is widely used in modern buildings worldwide. Modern high-rise buildings, large industrial factories, and especially some data centers require huge amounts of electricity. Faced with the huge load that requires hundreds of thousands of amperes of strong electrical current, safe and reliable electrical equipment should be chosen. Electrical busway is a good choice. The electrical busway system is an efficient distribution device for conveying current, especially suitable for the needs of economically reasonable wiring in increasingly high buildings, large-scale mining factories. We have installed this electrical busway and its associated distribution transformers for their electrical distribution systems for data centers in many countries throughout the world.

Compared to electrical power cables, the advantages of electrical busways are more obvious, so many industrial & commercial buildings now widely use electrical busways to replace power cables. What are the obvious advantages of electrical busways?

- Large current carrying capacity;

By using copper or aluminum as conductors, electrical busway is of extremely high conductivity and can carry large currents. Its rated working current can reach up to 6300A, far exceeding the 800A of traditional power cables.

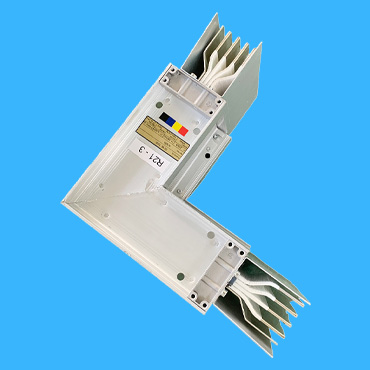

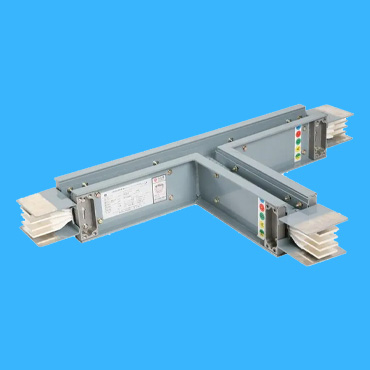

- Modular design and flexibility

Used a modular design, with multiple reserved plug-in interfaces, it can easily add branch circuits and complete expansion without power outage. This design not only improves construction efficiency, but also enhances the flexibility and scalability of the whole electrical distribution system. Meanwhile, this modular design will save your laboring costs a lot for making the power cable joints.

3.Good heat dissipation performance

The heat dissipation effect of electrical busway is significantly better than traditional power cables, which dissipate heat through air conduction and maintain a lower temperature rise even during high current operation. This enables it to operate stably even in high temperature conditions.

- High reliability and long service life;

The service life of an electrical busway usually exceeds 30 years, and the shell material such as high-strength non-magnetic aluminum magnesium alloy has excellent corrosion resistance and impact resistance, reducing the frequency of equipment replacement and maintenance costs a lot.

- High safety;

The enclosure of an electrical busway is usually made of metal materials, which have good performance of fire resistance, flame retardant, and high temperature resistance. Its internal insulation material also has flame retardant properties, which can effectively prevent the fire. In addition, the short-circuit load capacity of the electrical busway is strong, due to its high conductivity and it can almost switch off the whole electrical distribution system when a short circuit occurred.

Adopting a separate air insulation type, the safety net distance and creepage distance between phases are far greater than the standard requirements; The internal insulation components are made of high-strength engineering plastics, which improves the electrical busway’s resistance to vibration and thermal stability; The special construction adopted by the joint can prevent misoperation during installation.

6. Free to change the number of branch circuit

The electrical busway socket adopts a modular design, and the entire system can reserve a large number of sockets. Ensure that the load can be connected to the electrical bus way unit in the shortest possible path, and there is no need to change the bus system for the addition, movement, or renovation of workshop equipment.

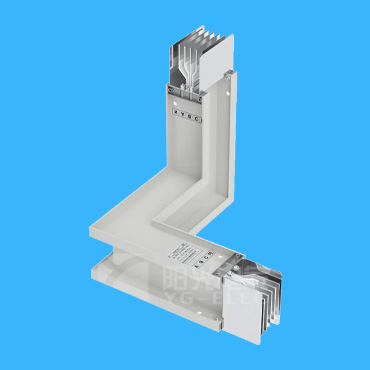

7. Compact design, much smaller in an overall dimension.

The electrical busway casing adopts rolling forming, small size, and exquisite appearance, greatly improving the long load capacity. It can carry a load of 60Kg at the center of the bus with a span of 6m, and the deflection does not exceed 10mm.

8. Easy installation & its maitainance work;

The electrical busway installation process is very convenient and flexible, greatly saving installation time and labour costs.

Although the cost of electrical busway may be slightly higher compared to power cables, compared to various accessories used for wiring and the entire power system, the use of electrical busway can greatly reduce construction costs. Therefore, both in terms of cost and actual use effect, the advantages of electrical busway are very obvious, and the future development trend will also be getting better and better.

Conlusion;

PowerTel and his experienced engineers are able to provide you a custom design & production of this electric busway and its associated distribution transformer, LV panle board and MV electrical switchgear, thus to assure a seamless,safe & reliable connection of your whole electrical system.