Your Reliable Supplier of Cable Tray & Raceway in China since 2010

As a professional manufacturer of cable tray & raceway over 20 years, we are able to provide you a full range of products and used in industrial & commercial buildings, electric utilities, oil & gas and petrochemical sectors.

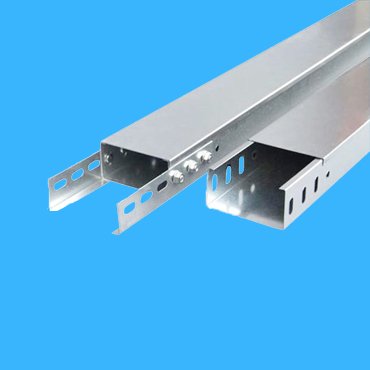

What is a Cable Tray & Raceway

Referring to NEMA & IEC standards, cable tray & raceway is mainly used to lay and protect wire & cable lines to avoid potential damage caused by external factors during operation. A rigid structure with cable support is composed of straight cable tray, tray elbow, tray tee & cross, supports and hangers. The three most common types of cable tray & raceway in the market are: channel cable tray, perforated cable tray and ladder type cable tray.

PowerTel & its associated factory will help you to select a proper type cable tray & raceway to fit your cable tray wiring system.

Cable Tray & Raceway by its materials

it is made of aluminum or aluminum alloy, galvanized steel, hot dipped steel, 316 stainless steel or fiber glass.

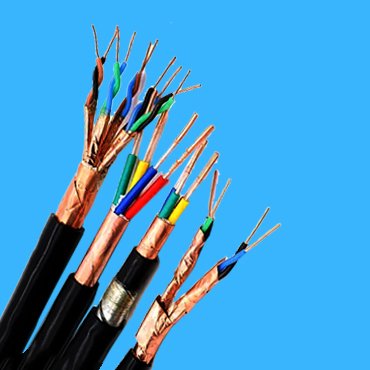

It is a fully enclosed cable tray, which is suitable for laying communication cable, thermocouple cable and other high-sensitive control cable. It has good effect on shielding interference of control cable and protection of cable in heavy corrosion conditions.

It has the advantages of light weight, large load, simple structure, convenient installation, good heat dissipation and permeability, etc. It is applicable to the installation of power cables and the laying of control cables.

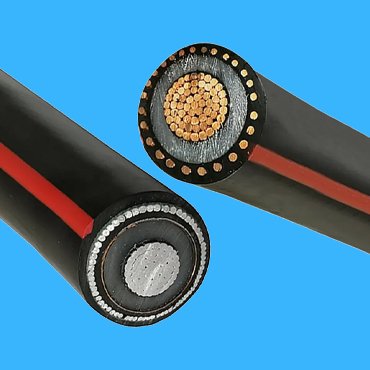

It has the characteristics of light weight, good ventilation and heat dissipation. It is suitable for laying cables with large diameter, especially for laying high and low voltage power cables.

Necessary accessories to fix or to support the installation for Cable Tray & Raceway

Well-equipped with Manufacturing Facilities

From CNC Punching, Roll Forming, and Robotic Welding , with our well–equipped hot galvanized plant ,we used top–notch European–standard electronic control equipment and measuring devices to ensure adherence to various quality standards for our cable tray & raceway.

Fast Delivery Time

Having a large inventory, plus our big production capacity for cable tray & raceway, it allows us to have shorter production and delivery times, as we can quickly and easily modify our production rate based on the size of the order, which is quickly meeting and surpassing the expectations of our customers.

Custom Design & Fabrication for Your Cable Tray & Raceway

we understoond, you are always having some special requirement of these cable tray & raceway; With our extensive engineering and manufacturing capabilities, our engineering team is ready to work with you to develop a cable tray and raceway solution that meets your specific needs.

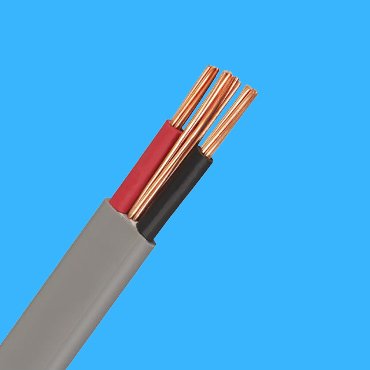

Related Product

Guide to select a proper cable tray & raceway

The cable tray & raceway used in industrial & commercial buildings and power control room for utilities customers, the first thing we need to consider is the product quality, whether it compliant to related standards.

Secondly, we need to take care is its color, structure and its configuration, ensuring to have an easy & convenient maintenance work in future.

The cable tray & raceway installed outside the building in the open air, if located near the seaside or in a corrosive area, must have physical properties such as anti-corrosion, moisture resistance, good adhesion, and high impact strength;

Load for cable tray & raceway

The load of cable tray & raceway is divided into static load, dynamic load and additional load.

Static load refers to the type, number, outer diameter weight/unit length of cables laid in cable tray, which are listed and counted according to different routes of cable laying.

Dynamic load refers to the weight of construction and maintenance personnel during the installation and maintenance of cable tray. For light cable tray, dynamic load is generally not considered, that is, people are not allowed to stand or walk on the cable tray & raceway. If it is necessary to consider standing people, the span should be appropriately reduced.

The additional load only refers to the load formed by ice, snow, wind, and electromagnetic forces outdoors, which is related to the natural meteorological conditions of the installation site and the properties of the charged body. Calculation should be based on various conditions in the design.

Installation guide for cable tray & raceway

Firstly, we need to take the considerations into the safety when we are going to install the selected cable tray & raceway, such as ambient temperature ,ventilation condition etc.

- Keep enough safety distance we need to consider when When the cable tray is horizontallyor verticallyinstalled.

- In some hazardousareas, we have to use the cable tray with a higher performance of anti-corrosion; if necessary, we need to choose the cable tray made of aluinum alloy, although it is in a higher cost.

- Fire protectionis another important factor we need to consider; at this time, raw materials for making this cable tray having a better performance of fire or flame retardant need to be selected.

- in electrical distribution system, shield electromagnetic interference, we need to consider this factor when we install the cable tray. Sunlight & ultraviolet rays exposure to the cable tray, corrosive liquids and easy-fire dusts , all these factors would have an impact to the cable tray.

- In some dusty places, we need use to some special materials with a good ventilation condition to cover the cable tray to avoid the dust penetrate into the cable tray.

7. Cables with different voltages and different purposes should not be laid in the same cable tray:

(1) Cables above 1kV and below 1kV:

(2) Double circuit cables supplying power to primary loads along the same path;

(3) Emergency lighting and other lighting cables:

(4) Power, control, and telecommunications cables.

when there are several power cables with differenr voltage level in a same cable tray, we have to use a spacer to seperate them individually.

8. When the length of the steel straight section exceeds 30m and the aluminum alloy cable tray exceeds 15m, or when the cable tray passes through the expansion (settlement) joint of the building, an 0 to 30mm compensation allowance should be reserved. The expansion connection plate should be used for its connection.

9. The selection of cable ladder and tray width and height should meet the requirements of filling rate. Generally, the filling rate of cables in the ladder and tray can be 40% -50% for power cables and 50% -70% for control cables.