Your Best Coaxial Cable Supplier in China since 2000

- ISO 9001 & 14001 Certificated Factories

- Mothly Production Capacity over 50,000 KM

- Complete Product Chain for Cable & its hardware & accessories

- Custom Solution for your Telecommunication System & worldwide Supply Record

Coaxial Cable

Over 20 years manufacturing experience, it made us enable to provide you a complete range of RG & RF coaxiable, leaky coaxiale cable and its associated hardware & accessories. Meanwhile, Our expert engineers will collaborate closely with you to continually refine the standard selection of coaxial cables and technologies, as well as create a specialized solution for your telecommunication system.

RG Coaxial Cable

It contained two main categories, 50 Ohm, including RG 58, RG 174, RG 213, RG214, RG 223 Coaxial Cable ; and 75 Ohm, including RG 6, RG 11, RG 59, RG 175 Coaxial Cable.

RF Coaxial Cable

Leaky Coaxial Cable

Product Feature Box

Cutting-edge Production Lines

Dozens of cutting–edge production lines and hundreds of supporting equipment imported from Europe and U.S are arranged in an impressive manner. The top–notch equipment serves as a strong assurance for the production of first–rate coaxial cables.

A High-tech Enterprise

Equipped with advanced business philosophy, strong technical strength, and forward–thinking, we are a high–tech enterprise that produces a complete range of coaxial cables at the world‘s advanced level.

Deep Understanding of the Market

For coaxial cables, We have a deep understanding of the market that has enabled us to become a leading supplier in the industry and reward a positive recognition.

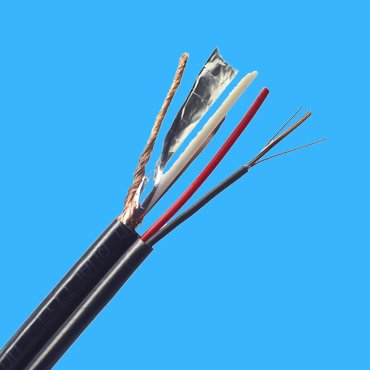

Analysis of Signal Transmission Characteristics of a Best Coaxial Cable

For a coaxial cable, it is an insulating medium with a certain thickness surrounding the inner conductor in the center; The outer conductor is a tubular outer conductor, and the surface of the outer conductor is protected by insulating plastic. It is an asymmetric transmission line, where the direction and return conductor axes of the current coincide with each other. When the signal passes through the coaxial cable, the established electromagnetic field is closed and there is no electromagnetic field around the cross-section of the conductor. Therefore, internal signals have little impact on the outside world. The internal electric field of the cable is established between the central conductor and the outer conductor, with a radial direction. The magnetic field, on the other hand, is centered around a central conductor and forms multiple concentric circles. The direction and strength of the field vary with the direction and magnitude of the signal. The loss of coaxial cables on transmission signals mainly includes the following aspects;1. resistance loss, 2. Dielectric loss, it refers to the loss of a signal caused by the dielectric (insulator) between the central conductor and the outer conductor of a coaxial cable. 3. Mismatch loss, it is mainly closely related to the physical structure of coaxial cables. 4. Leakage loss, it refers to the signal radiated through the braided gap of the cable shield.

Finally, The shielding characteristics of coaxial cables are an important indicator reflecting cable quality; If a coaxial cable cannot meet the transmission requirements for shielding strong interference signals, auxiliary measures can only be taken to solve the problem. For example, adding metal tubes or magnetic rings to the outer conductor to shield or short-circuit signals; Add modems at both ends of the transmission line to transfer frequencies and avoid interference; Or increase the video amplitude, suppress interference etc.

Related Products

What is a coaxial cable used for ?

Coaxial cables are typically used to transmit cable TV signals, video signals, digital signals, and various other high-frequency signals

What types of coaxial cable?

Coaxial cables are divided into two categories: 50 Ω baseband cables and 75 Ω broadband cables. Baseband cables are divided into thin coaxial cables and thick coaxial cables. The baseband cable is only used for digital transmission, with a data rate of up to 10Mbps. Broadband cable is a standard used in CATV systems, which can transmit both analog signals using frequency division multiplexing and digital signals. Coaxial cables are more expensive than twisted pair cables, but their anti-interference performance is stronger than twisted pair cables. When there are many devices that need to be connected and the communication capacity is considerable, you may need to use coaxiale cable or fiber optic cable.

A helpful guide to select a proper type of coaxial cable

The standards for selecting a coaxile cable varied depending on their purpose. A high-quality coaxial cable has a compact and sturdy structure in appearance, with a smooth and flexible outer sheath. The woven mesh is thick and dense. In addition to the number of braided wires, the braided angle of the shielding layer is less than 450 degree. However, some manufacturers, in order to save materials, have cable braided angles greater than 700 degree , which can deteriorate the shielding characteristics of the cable. The central conductor or insulation part of coaxial cables with poor craftsmanship can be pulled out. There are two types of aluminum foil for the outer conductor of four shielded cables: bonding and overlapping. Overlapping is the process of wrapping aluminum foil on the physical foam insulator of a coaxial cable, with a partial overlap of 3mm at the joint. Bonding is the bonding of aluminum foil with physical foam insulators. Bonding has better shielding performance than overlapping. The best four shielded cables are all bonded. The coaxial cables used in cable TV systems and high-frequency broadband monitoring systems are mostly high-frequency physical foam cables. Due to the poor low-frequency anti-interference characteristics of cables, the external interference intensity and frequency in the low-frequency range are high. So, intentionally avoiding frequency bands below 5MHz in use. However, the frequency band of the above system is wide, so when selecting cables, special attention should be paid to the attenuation characteristics and reflection losses of high frequencies. When cable TV transmits signals in reverse, the noise from all terminals will converge to the front end. Therefore, in order to minimize external interference on the cable, 4-layer shielded or aluminum tube cables are usually selected. In monitoring systems, it is currently common to use video baseband transmission methods, and polyethylene solid cables are commonly used. Due to the frequency range of the video being 0-6MHz, this type of coaxial cable is produced using recycled plastic with high impurity content as the dielectric material. Sometimes there are no significant issues when transmitting low frequency (video). Solid cables are usually single-layer shielded, and their anti-interference characteristics cannot be compared to multi-layer cables. In video baseband transmission, using high-frequency physical foam cables has lower signal attenuation. However, using inferior dielectric materials in foam cables results in poorer transmission performance compared to polyethylene solid cables. This is because the dielectric constant of inferior materials increases while the conductor diameter remains unchanged, resulting in a serious deviation of characteristic impedance. If the foaming degree of the medium is not enough, it can also cause the above situation. The most effective method for identifying dielectric materials is to test the high-frequency attenuation value of the cable. If the material purity and foaming degree are not sufficient, high-frequency attenuation will significantly increase. During the production process of cables, if the processing quality is poor, it can also cause irregular roundness of the outer conductor or eccentricity of the central conductor. This directly affects the reflection loss, i.e. impedance, of the cable. Thus, the image transmission quality is affected, and the impedance index can only be measured by network analyzer. During construction, the appearance of the cable should not be damaged. Otherwise, it will affect the impedance and shielding characteristics of the coaxial cable. When connecting cables, remember not to twist the wires together at will. Special connectors must be used for connection. Before production, reference should be made to the joint production method of coaxial cables. This should be given special attention. According to statistics, there are more than 80% of the faults are caused by cable joint & cable connector.