A Best Control Cable Manufacturer in China & India

We can supply a wide range of control cables used in automation process, electronic control systems, and in power substatios, which can keep your projects running safely & stably even in a harshest environment.

- Over 30 years experience in R & D

- Tailored options & designs for your individual needs

- Cables used in a wide range of applications in different industries

- Control cable manufactured to standard, IEC & EN, BS, AS, VDE, JIS, ASTM & UL

What is a Control Cable

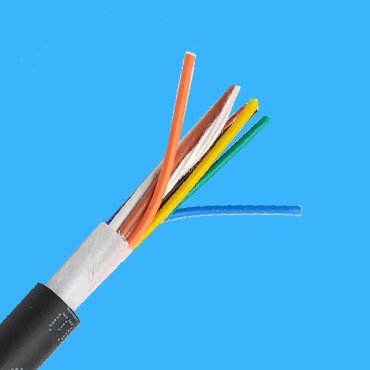

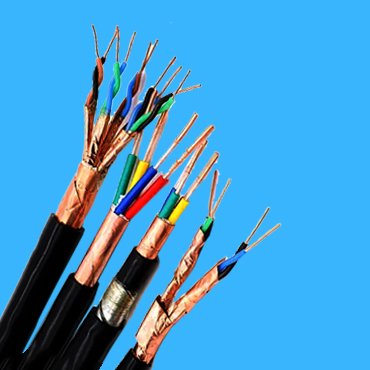

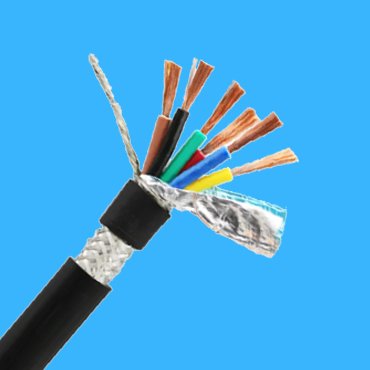

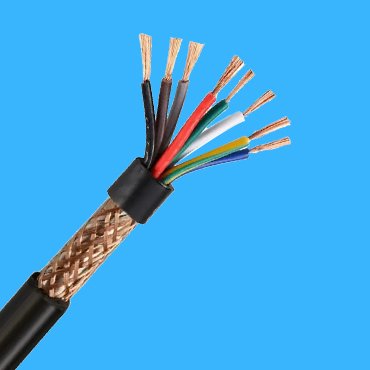

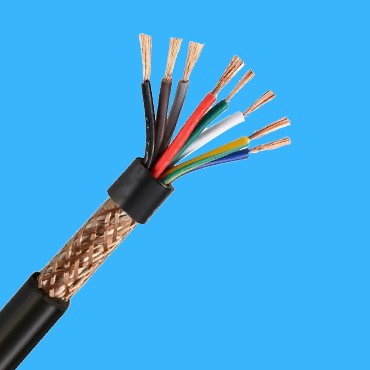

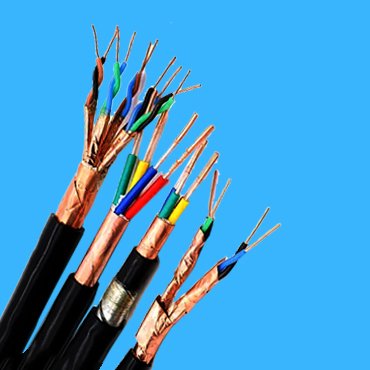

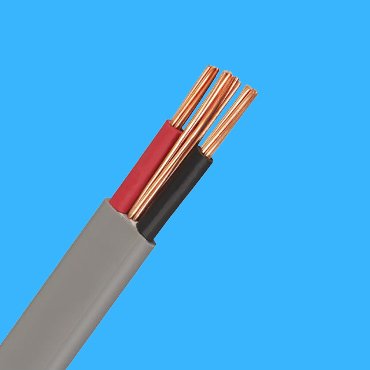

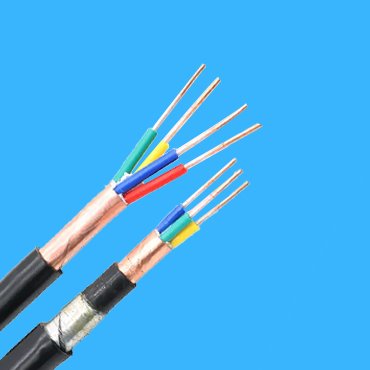

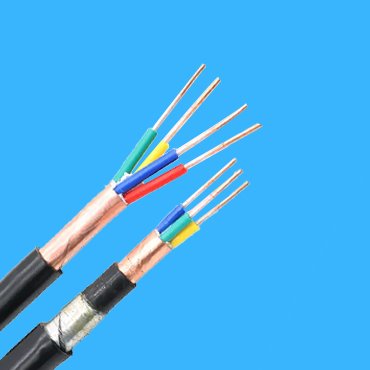

In electrical distribution system, a control cable is always used to transmit a precise signal to various electrical equipment, making sure all these electrical equipment running smoothly & efficiently. Peeling off a control cable, firstly we will see a PVC outer sheath, a steel tape armoring layer, helically wound around the cable core,which is used to protect the control cable itself. And then it is insulation layer for the cable; a shielding layer by aluminum tape or a copper tape, which is very important for a control cable, making sure transmission signal is stable. Finally, we will see control cable core, which is up to 61 cores made up of stranded aluminum or copper wires and insulated by PVC or XLPE. some control cables are shielded by a braid layer to block signal interference from nearby equipment or devices. Based on our 30 years manufacturing experience, we can supply you different types control cable to meet your precise control & measurements for the best performance.

Control Cable by UL & ASTM Standard

There are XHHW/PVC Sheathed type TC Control Cable, XHHW/CPE jacketed type TC Control Cable, XHHW/XLPO sheathed type TC Control Cable, installed in cable trays, raceways, or an aerial installation suspended by a messenger wire.

Refer to standard of UL 1277 & 1581, ICEA S-95-658 & IEEE 383; FR-XLPE Insulated, PVC Jacketed

Refer to standard of UL 1277 & 1685, ICEA S-58-679 & IEEE 1202; FR-XLPE Insulated, CPE Jacketed

Refer to standard of UL 1277 & 1581, ICEA S-95-658 & IEEE 1202; FR-XLPE Insulated, XLPO Jacketed

Copper Conductor

PVC/NYLON Insulated

PVC Outer-Sheathed

CU Conductor per ASTM B3 & B8

FR-XLPE Insulated,Copper Tape Shielded

PVC Sheathed Control Cable

CU Conductor

FR-XLPE Insulated

Copper Tape Shielded

CPE Sheathed

Control Cable by IEC & EN Standard

In accordance with the standard of IEC 60228 & IEC 60502, it is the control cable sheathed by PVC and inslaued by XLPE.

Control Cable by VDE Standard

Product Feature Box

ISO 9001 & 14001 Certificated Factory, ensuring a high quality of different types of control cable.

UL certificated factory, made us have capaities to make various types of control cable, fully complied with UL standards.

CE Certificated factory, is well serving customers from European countries, control cable fully meet IEC & EN standard, BS, VDE & NFC standard etc

Over 30 years Experience on R & D for Control Cable for different applications; we can offer you a tailored design & fabrication for your custom fit.

Production Line for Control Cable

Our success is attributed to well–equipped production lines, dedicated workers, and scientific management. We have achieved brand recognition in over 80 countries around the world.

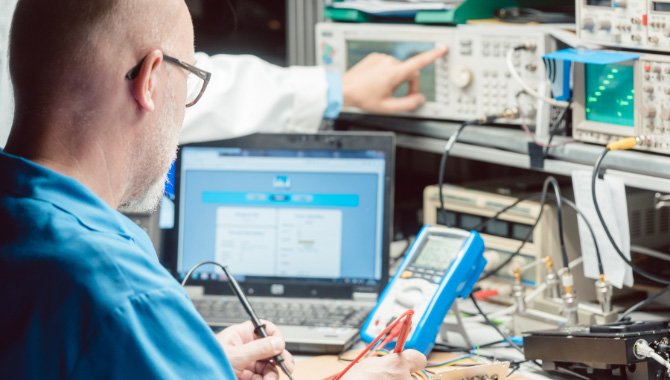

Strict testing of manufacturing process

We did take a strict testing of each manufacturing process, making sure all control cable fully meet the original requirements of customers.

Individual Design for a Control Cable

Through years of manufacturing experience, we are able to provide you a wide range of controal cable for your various applications as well as its cable joints.

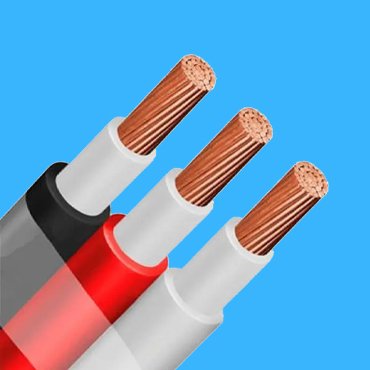

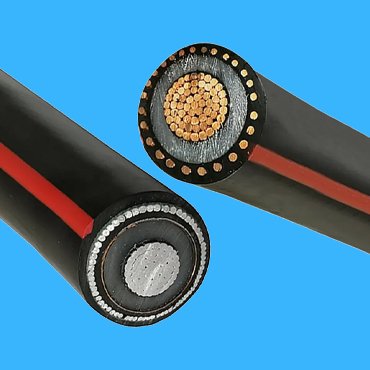

Difference between Power Cable and Control Cable

- for a power cable, it is used to transmit the power resource between two electrical substations or transmit the power resourceto different loads.

- they are different in cable structure , control cable is comparatively simple and the conductor size is quite small, not exceed 10 square millimeters ,but for a power cable, it is increasingly complicated when the voltage level going up to 500 kV.

- Difference in cable cores and its coloring method.

For a power cable, it normally has one core or three cores plus a neutral wire when it is necessary, while for a control cable, for a specific requirement, it has up to 61 cores for heavy-duty signal transmission work.

Related Product

What types of Contol Cable

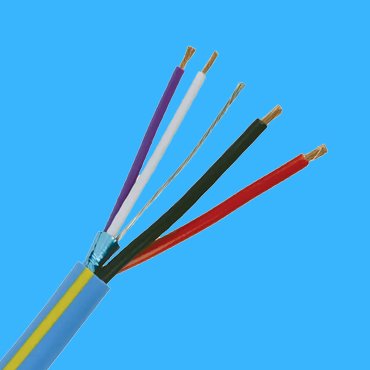

Control cables are suitable for wiring electrical control equipment and instruments, monitoring and control circuits, electrical protection, and measurement power distribution units under service conditions, with a rated voltage of 450/750V AC. The long-term working temperature of PVC insulated cables is 70 ℃; and long-term working temperature of cross-linked polyethylene insulated cables is 90 ℃; and temperature of cable laying should not be lower than 0 ℃. there are following types:

- Solid copper/aluminum conductor , PVC ordinary insulated wire, unsheathed wire. Suitable for wires and cables used in power plants, daily appliances, instruments, and telecommunications equipment with AC voltage of 450/750V and below.2. for a control cable with PVC insulation, and CU or AL conductor , often referred to as flexible wires.Due to the softness of the wires, they are often used for electrical traction and motor connections, as well as in situations where the wires often move slightly.3. Solid Copper/aluminum conductor, PVC insulated, PVC round sheathed cables, it often referred to as sheathed wire, single core wire is round, and double core wire is flat, often used for surface mounted wires. 4. Solid conductor, PVC insulated, PVC flat sheathed cables.Suitable for occasions with high mechanical protection requirements, damp conditions, etc. It can be applied in an open or concealed manner.5. Stranded wire, PVC insulation, PVC sheath, circular connection flexible cable. Suitable for building intercom, anti-theft alarm, fire protection, smart grid system. 6. Copper core, PVC Insulated and twisted control cable, Commonly used in household appliances, small electric tools, instruments, control systems, broadcasting and audio systems, firefighting, lighting etc.We still have some other types of control cable, please consult it with our exper engineers for a right type of control cable for your project.