Your Reliable Electrical Insulator Manufacturer in China

Being a professional manufacturer over 20 years, we are committed to offer you a wide range of electrical insulator and insulator string with a highest quality and best possible cost, with an added value of

Technical consulting at very beginning of your project

Individual Designs for your projects

On-site technical support and training

What is an Electrical Insulator

Electrical Insulators are essential components in power systems, such as power plants, power transmission and distribution lines, as well as their associated substations and some electrical equipments.

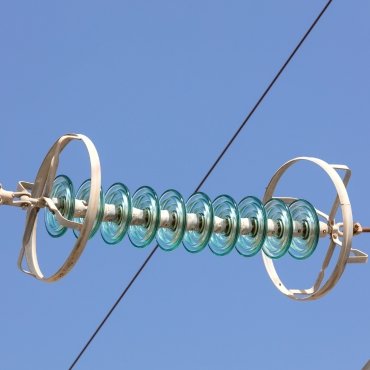

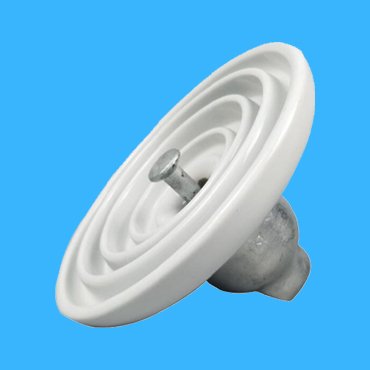

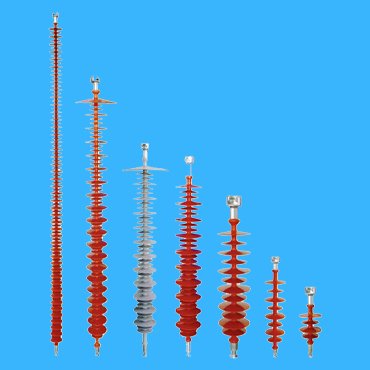

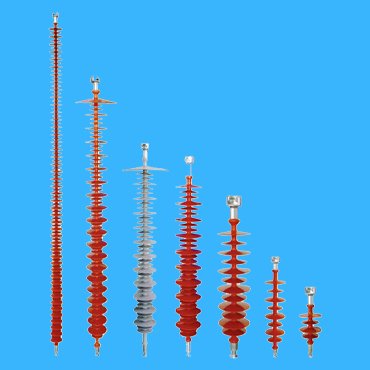

There are three main types of electrical insulator, and they are made of composite polymer , fabricated with procelain or a glass; it looks a little different, but all electrical insulators have two main parts, the one is insulation to isolate with power conductors, and the other one is a connection part to fix the insulator on electric poles or towers properply. The function of an electrical insulator is to withstand the voltage and supply meachnical stress to bridge a power conductor and pole or tower. PowerTel and its related factories can offer a wide range of electrical insulator and insulator string for use on power plants, power transmission & distribution lines and its associated substations up to 500 kV. We aim to provide you a package solution that are reliable, easy to install, and meet the highest standards of quality and performance at your lowest cost. We test and verify the electrical insulators and strings of insulators in accordance with international standards such as IEC, DIN, and ANSI. and we offer an on-site technical support and training for the installation & maintainance of these electrical insulators and insulator string.

Electrical Insulator by its material

According to its raw materials, it has glass insulator, porcelain insulator and composite polymer insulator.

A higher corrosion resistance, due to their special coatings & materials

An excellent pollution-resistance, strong prevention from flash accident

Electrical Insulators by its function

According to its function, it would be Suspension Insulators,Guy Strain Insulator, Line Post Insulators, Shackle Insulators, Substation Post Insulators,Bushing Insulators, Cap and Pin Insulators and Crossarm Insulators etc.

Product Feature Box

Individual Design for your Project

Over 50 expert engineers are ready to provide the right solutions to all of your challenges for electrical insulator and work closely with your engineers for a specific design.

In-house Testing Facilities

We use our own internal testing facilities to ensure that all electrical insulators are of the highest quality before shipment. Routine and sample testing is conducted as well.

Custom Insulator String

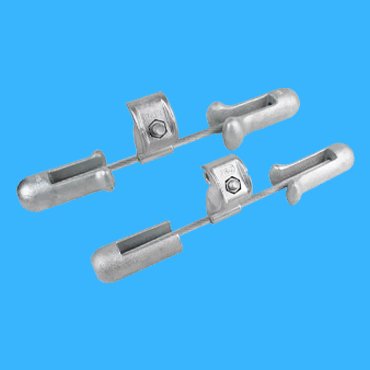

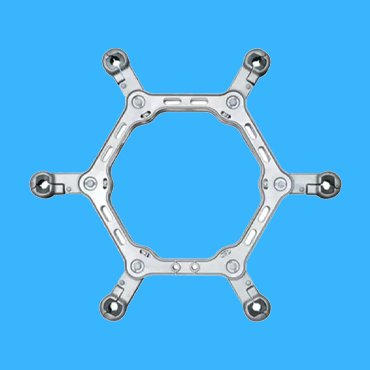

Through years of experience , we can provide you a tailored insulator string solutions for all types of electrical towers & poles, and its associated tension & suspension clamps for conductors; these insulator strings will be pre-assembled and tested before the shipment.

Advantages of a Composite Polymer Electrical Insulator

The epoxy glass fiber rod has excellent anti–pollution properties, making it capable of preventing flash accidents and eliminating the need for clean–up in heavily polluted areas, while also providing superior electrical performance and strong mechanical strength for reliable and safe operation;

To optimize the size design of the shed type structure based on aerodynamic principles, reasonably disposing the grading ring can prevent electric current leakage, protect the surface from corrosion due to electric arcs, and increase the service life of a composite electrical insulator;

This shed has excellent sealing performance and anti-electrolytic corrosion properties. It is designed for use in temperatures ranging from -40℃ to +50℃ and has excellent anti-ageing and corrosion resistance, as well as excellent resistance to brittleness and creep deformation, and an unbreakable, anti-bending property. Additionally, it is lightweight and small in size, making it easy to transport and install.

The composite electrical insulator has better mechanical and electrical performance than other types of insulator , and its safe operating tolerance is substantial.

Our Dip-coating Process for Porcelain Electrical Insulator

It is a newest process technology for manufacturing porcelain electrical insulator, mechanical equipment is used to coat ceramic insulators with RTV coating. This immersion coating results in a smooth and flat surface on the insulators, without accumulation or bubbles, and no dripping in the joints. The coating thickness is uniform and the appearance quality of products produced by this method is superior to that of insulators produced by spraying and brushing technology. Additionally, production is highly efficient and cost–effective, and there is no environmental impact or safety hazards to operators in the production process, meeting the requirements of factory production.

Related Product

Testing Items for a composite polymer electrical insulator

- Routine test : Mechanical routine test & visual verification

- Sample test: Verification of dimensions, end fittings and tightconnection with insulator housing and of the specified mechanical load;

3. Type testing items for an electrical insulator , it would be a little complicated and it need to be tested in a third party , including the test of dry lightning impulse withstand voltage; test of wet power frequency & control of the slope of the strength-time curve of an electrical insulator etc.

4.Designing tests: Tests on interfaces and connections of end fittings; Pre-stressing-Sudden load release pre-stressing ;Thermal-mechanical pre-stressing; Water immersion pre-stressing

5.Tests on raw material for making shed and housing part of an electrical insulator ; it included Hardness test; speed-upweathering test; Tracking and erosion test; Flaming class test.

Finally, it is some testing items on the core materials

the one is Dye penetration test; and the other one is Water diffusion test.