Your Reliable Supplier for Fiber Optic Patch Cord Cables in China

Over 20 years manufacturing experience, we can provide you a complete range of fiber optic patch cord cable and its associated accessories

- Connectors & adpaters

- Different types of Patch panel

- PLC Splitter

- Joint enclosure and cable terminal box

What is a Fiber Optic Patch Cord Cable

Fiber Optic Patch Cord Cable, it is a connecting material in a certain fiber optic communication system, used a lot in data centers, automation control system, and some other places drawing on its high transmission speed , low loss, and anti-interference properties. It widely used in CATV, EPON & GPON, FTTX projects and data center.

PowerTel & its associated factory has a monthly production capacity of one million Fiber optic patch cord with different types of connector in different polishing method. A patch chord cable in a Single mode fiber or multi-mode fiber, gray, orange or any special colors, and your tailored cable length.

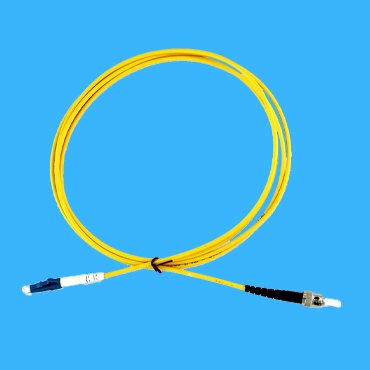

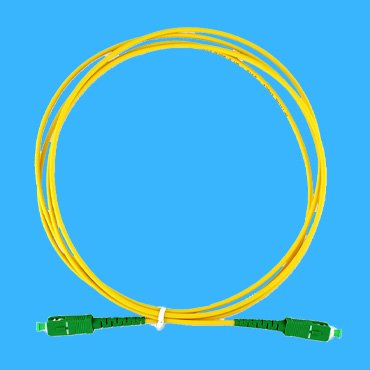

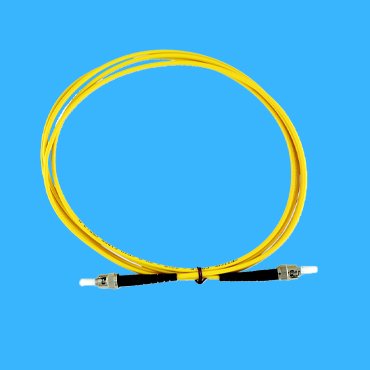

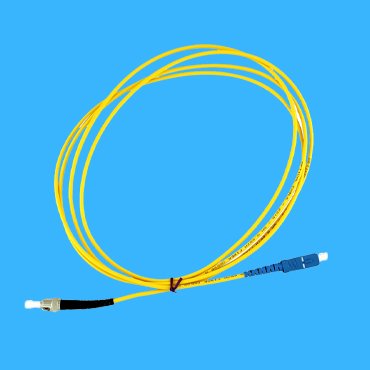

Fiber Optic Patch Cord Cables by its connector type

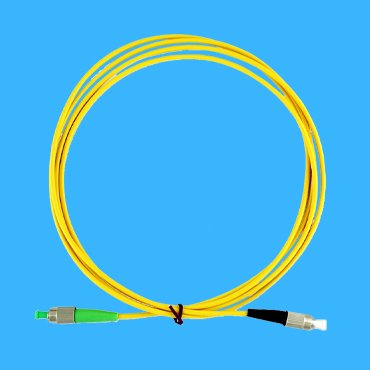

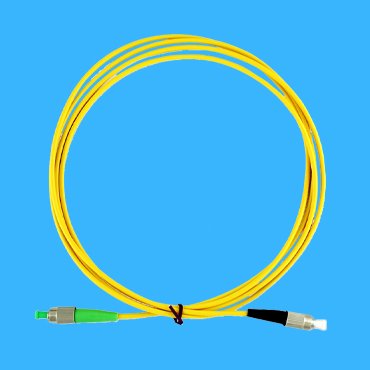

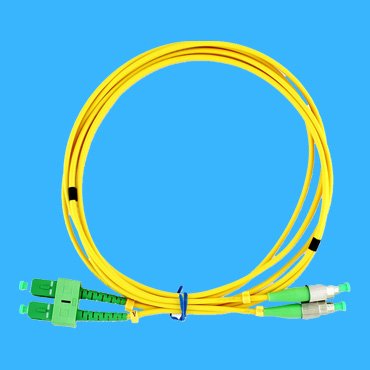

The external reinforcement method is metal sleeve, and the fastening method is turnbuckle. Generally used to fit into ODF ports and fiber optic patch panel ports.

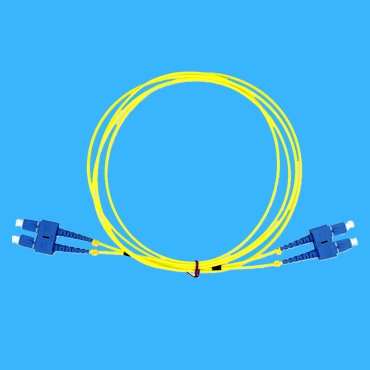

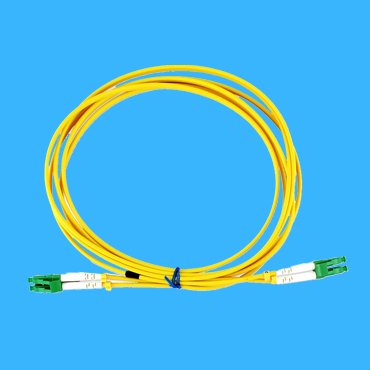

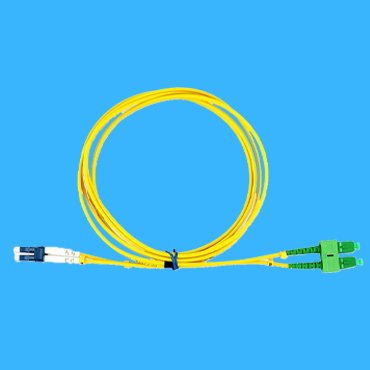

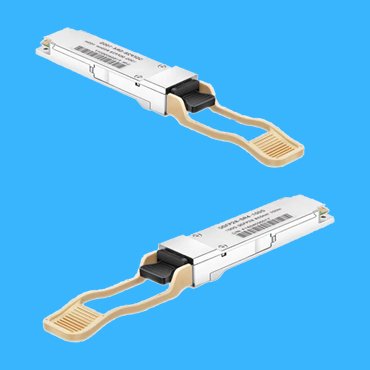

Used to connect GBIC optical module. Its shell is rectangular, and the fastening method is plug-and-pull latch type without rotation, and most used on router switches.

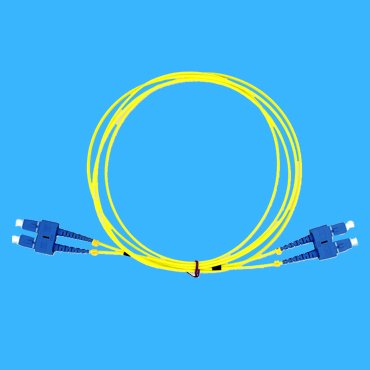

It commonly used in optical fiber distribution frame, the shell is round, and the fastening method is turnbuckle.

It used to connect SFP module, made of modular jack (RJ) latch mechanism with convenient operation and also used for routers.

Cable Color, on your request

Cable length, on your request

Cable Jacket: PVC, LSZH, Riser OFNR Rated or Plenum OFNP Rated

Cable diameter: 0.9mm, 2.0mm, 2.4mm, 3.0mm or 5.5mm

Cable Type: Simplex, Zip cord Duplex, Round cord Duplex

Cable length, on your request

Cable Jacket: PVC, LSZH, Riser OFNR Rated or Plenum OFNP Rated

Cable diameter: 0.9mm, 2.0mm, 2.4mm, 3.0mm or 5.5mm

Cable Type: Simplex, Zip cord Duplex, Round cord Duplex

Cable Jacket: PVC, LSZH, Riser OFNR Rated or Plenum OFNP Rated

Cable diameter: 0.9mm, 2.0mm, 2.4mm, 3.0mm or 5.5mm

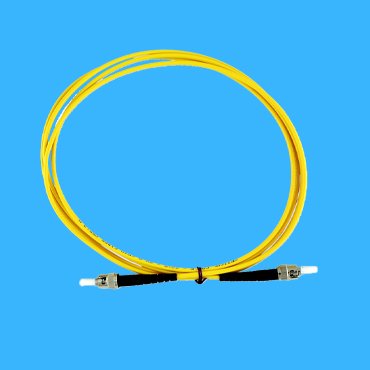

Simplex Fiber Optic Patch Cord Cable

Duplex Fiber Optic Patch Cord Cable

Product Feature Box

ISO Certificated Factory, assuring high quality of our fiber optic patch cord cable.

UL Certificated Factory, fully meet customers’ need in North American.

CMR Certificated Factory, Satisfied our clients in EU Countries.

60 assembly lines & large inventory, making sure to deliver your cables in 5 days.

Clean Workshop & Skillful Workers

The secret of our success is our clean workshop and skillful workers, who work hard to ensure that our products are of the highest quality.

Stringent Testing Procedures

By testing each processing step thoroughly, any errors or issues can be detected and corrected before move into next, thus to ensure a highest product quality.

Package Supply of Patch Cord Cable & its Related Accessories

Through years of industry experience, we are committed to provide our customers with a package supply of patch cord cable and its related accessories, thus will minimize your total costs while assure a consistent quality of all products we supplied.

Related Product

Normally, We can see that Fiber optic patch cord cable are already applied in the following industries & fields.

- Telecommunicationrooms for the backbone fiber network

- -Fiber to the home/Building/ projects: Fiber optic patch cord cablestransmit optical signals from backbone fiber optical cables to user terminals, providing gigabit broadband services for homes and business units, supporting high-definition video, online meetings, and other application

3.5G base stations and backbone networks: In 5G networks, fiber optic patch cord cables connect the base stations to the central network, ensuring low latency and high bandwidth telecommunication quality.

- 4. Data Centers

In a data center, fiber optic patch cord cables are used for linking servers, switches, and storage devices.

- Industrial Control and Medical Facilities

-Industrial Control: In nowadays precise manufacturing factory, fiber optic patch cord cables connect sensors and controllers to ensure real-time data transmission and improve production efficiency, thus to save labor cost for the factories and reduce the risks accordingly.

-Medical facilities: MRI, CT and other medical devices transmit these simultaneous data or images through fiber optic patch cord cables.

- 5. some Other Special Industries

-Military and Aerospace: drone communication and satellite data transmission, it can maintain a stable transmission even in a much complicated environmental condition.

How to judge a fiber optic patch cord cable in a high quality. We need to consider following technical parameters:

- it is a single mode fiber or a multi-mode fiber , and its wavelength and attenuation data.

- Connector models, before we order these fiber optic patch cord cable, we have to confirm the connector type and its polishing method, thus to fit your telecommunication equipment properly.

It included LC (high-density), SC (stable and durable), FC (seismic resistant), and MPO (multi-core integrated), which need to be chosen based on device compatibility.

- Two important technical index for a fiber optic patch chord cable

Attenuation rate : Less than 0.3dB is preferred, as it directly affects the data transmission distance.

Bending radius : Too small in bending radius for a patch cord cable will cause data loss, usually need to over 10 times of the cable diameter.

- Environmental adaptability

As we know, this fiber optic patch cord cable already used in most industrial areas, for most applications, it is a very cold area or a heating place, such as a data center or a bitcoin mining factory,if their ventilation condition is not so good. So it indeed has a strict requirement for the cable materials fire resistance or flame retardant and temperature resistance (-40 ℃~75 ℃) .