A Best Fiber Optical Cable Manufacturer in China since 2000

ISO 9001 certificated factory, Available in full range of

- Indoor optical fiber Cable

- In-outdoor optical fiber cable

- Outdoor optical fiber cable

- And its associated accessories & fittings

What is an optical fiber cable

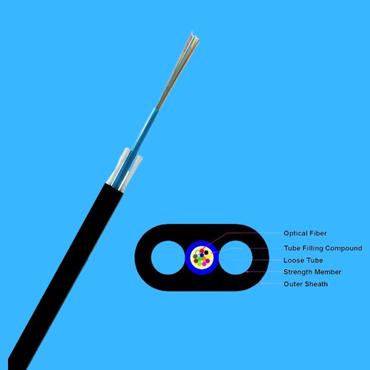

Optical fiber cable, It contained one, two or thousands of fibers to transmit voice, data & information. Some tubes used to protect fibers, some strength member used for a better breaking strength and some armoring layers used for anti-termite & anti-rodent, and finally sheathed by PE or PVC jacket, LSZH jacket or flame retardant jacket.There are three main types of fiber optical cable.indoor, outdoor and in/outdoor applications. According to its different applications, it can be categorized into duct, direct burial and aerial optical fiber cable, which include OPGW cable, figure 8 fiber cable and ADSS cable.

As a professional manufacturer of optical fiber cable over 20 years, we always used high-grade raw materials, like aramid yarn manufactured by DuPont USA. Meanwhile, based on our 60 production lines for optical fiber cable, a prompt delivery time is guaranteed here. Plus our professional technical support team, we have capabilities to offer you a custom design of different types of optical fiber cable, according to your unique needs or your technical datasheet.

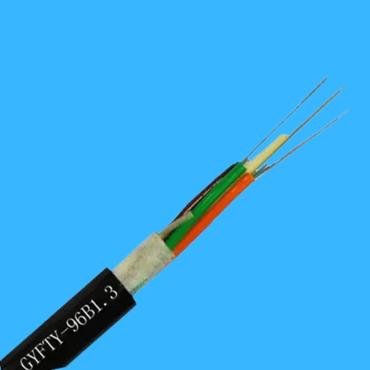

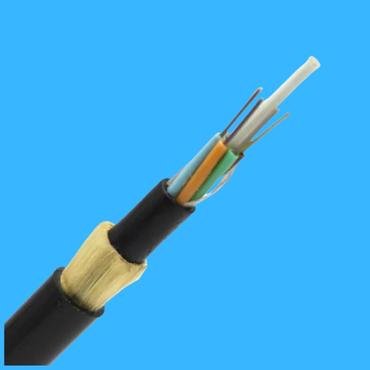

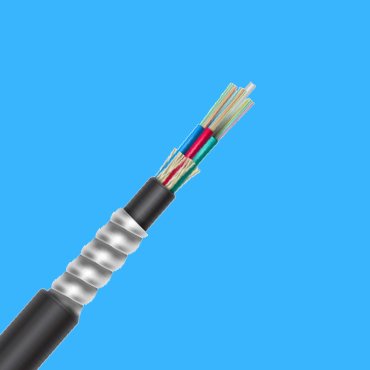

Outdoor Optical Fiber Cable

It used for outside plant application, flexible loose tube used to protect fibers, single or dual jacket applied with some armoring layers, thus to ensure the cable withstanding different environment conditions. It can be installed in ducts, direct buried in trench or installed between electrical towers & poles. A wide range of designs are available for your different installation conditions. Meanwhile, we can offer you a custom design & its quote based on your technical datasheet.

Gel filled central tube

TIA/EIA 598B color code

Corrugated steel tape armored

Installed in HDPE ducts

Fiber counts up to 432

Gel filled or Gel free loose tubes

Fiber counts up to 288

Gel filled or Gel free loose tubes

Fiber glass or aramid yarn strength member

RoHS compliant

Fiber counts up to 432

Simple & fast deployment & installation

Aerial installation

Fiber counts up to 216

Supported by galvanized steel wire

Fiber counts up to 288

UV resistance PE jacket

Anti-rodent, anti-termite fiber cable

Indoor Fiber Optic Cable

It used for indoor high-bandwidth application, which includes tight buffer simplex & duplex patch cord fiber cable, plenum distribution fiber cable, plenum breakout riser fiber cable, interlock armored distribution fiber cable, Indoor flat drop cable etc.

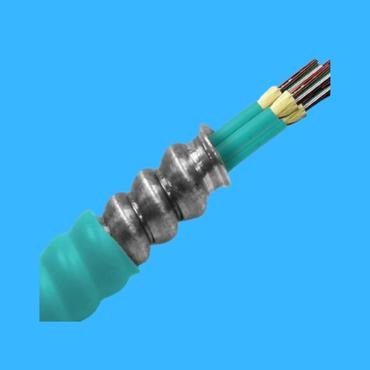

In-Outdoor Fiber Optic Cable

this series of fiber optic cable is for both indoor and outdoor applicatios, which can be installed in aerial, trays or ducts and in some riser or plenum locations.

Over 20 years manufacturing experience for fiber optical cable

Production line for fiber optical cable

Total 60 production lines, monthly production capacity of 20,000 cable kilo meeters, thus to assure a prompt delivery time for the full range of fiber optic cable

Custom Design & Fabrication

Custom design & fabrication for both indoor & outdoor fiber opitc cable to fit your special requirements to build up your new network or upgrade your existing network.

Drums or Reels for Fiber Optical Cable

Our sturdy drums or reels or your custom drums and well fixed in containers, thus to avoid the cable damage during whole shipping process.

Unmatched Properties of Optic Fiber & Fiber Optic Cable

Compared with traditional copper Ethernet cables, fiber optical cables using optical pulses to flow these data & information, other than through electrical signals, which has following special & unmatched properties:

-Ultra high speed: in terms of theoretical calculation, Data travels through these optical fibers at nearly 70% the speed of light.

– Extremely Low attenuation : over long distance transmission, it is as low as 0.2 dB/km and it can transmit data over hundreds of kilometers not using a repeater.

-Anti interference: it is a kind of di-electric or non-metal materials ,which is not affected by electromagnetic radiation, good to use in some complex conditions.

In addition, with the rapid decline in fiber optic prices, the cost of network construction has decreased a lot.

Related Product

Properties of an optical fiber

optical fiber is a key component in a fiber optical cable, and fiber attenuation is a most important factor;

The main factors that cause fiber attenuation include: intrinsic, bending, squeezing, Impurities, unevenness, and Fiber splicing.

Intrinsic: refers to the inherent loss of optical fibers, including Rayleigh scattering, inherent,Absorption, etc; Bending: When the fiber is bent, some of the light inside the fiber will be lost due to scattering; Loss caused by falling; Squeezing: Damage caused by slight bending of optical fibers when squeezed; Impurity: The light absorbed and scattered by impurities in a fiber that propagates in the fiber; Fiber splicing ,The loss generated during fiber optic splicing; This puts forward high requirements for the manufacturing processes of various optical fiber manufacturers, such as how to control the attenuation of optical fibers well.

One or more optical fibers housed in a loose tube or a tight-buffed tubes that forms an optical unit and one or more optical units stranded or centralized in circle way, with an outer sheath by using PE, FRPE or LSZH, and in hazardous applications, one or two armoring layers applied to protect the cable properly and aramid yarn/Kevlar to strengthen cable tensile strength for a large span length when it required.

In China, the “East Data West Computing” project ,through our built-up fiber telecommunication & power grid infrastructure, it efficiently connect the huge computing demand in the east and rich power resources in the west, made it possible & feasible.

Future development of the industry of fiber optical cables.

- * * 5G and the Internet of Things * *: 5G base stations relyon fiber optic cable to transmit huge of data & information, and intelligentcities & communities, Industry of AI, new data centers, all need the support of this ultra-low latency network.

- * * Space Division Multiplexing (SDM) * *: By using multi-core optical fibers to increase single cable capacity, it breaks through existing bandwidth bottlenecks.

- * * Quantum Communication * *: Fiber optic is the core carrier of quantum key distribution (QKD), for information security.

In accordance with the industry predictions, the market for fiber optical cable is expected over 10 billion US dollars by 2025, Driven by quantum computing, 6G telecommunication network, new data centers and AI-driven industries, the boundaries of speed, security, and connectivity will be pushed forward again & again. By 2030, experts predict that the global market for fiber optic cables will be more than $150 billion.

Installation Guide for Fiber Optical Cable

The main methods of laying Fiber optical cables include pipeline laying, direct burial laying, overhead laying, and underwater laying.

1.Before laying the optical fiber cable, the model, specification, and material of the cable should be checked to ensure that they meet the requirements of the design documents and have quality certification documents.

2.Visual inspection to the fiber optic cable need to be done before install the cables. The surface of the insulation layer should be flat, uniform in color, and undamaged. The A/B (head and tail) ends should be well sealed. The optical fiber bundle is composed of different colored optical fibers, and the colored yarn with full color identification should be spiral wound outside. The color code (or full color code) should be clear and complete.

3.When laying optical fiber cables on the ground, they should be laid in designated cable tray areas or independent protective pipes according to the design documents; When laying optical cables underground, the protective tube (bundle) and cable well should be cleaned to ensure cleanliness and smoothness; When laying optical cables in the control room, they should be laid in independent cable trays.

4. We need to follow the minimal bending radius of a fiber optical cable when install these fiber optical cable, other pulled them brutally. When laying optical cables, the bending radius of the cable should not be less than 20 times the outer diameter of the cable. When threading the protective tube, steel wire should be used for guidance and talcum powder should be applied.

5.Plan the direction of cable laying to minimize distance, branching, and cable joints, and ensure tight connections;

6. It is best to use a single bus method, connected by a unified communication trunk through a branching device, and not laid in a radial star shape;

7. The number and distance of branch points on both sides of the main control station (for systems with a main control station) should be as consistent as possible, which can better ensure the matching of network impedance;

7.1 The branching device should be as close as possible to the control station or operation station;

7.2 Both ends of the network should be connected to a 75 Ω terminal resistor or terminator;

7.3 The distance between fiber optical cables and high-voltage cables should be at least 40cm/kV, and if necessary, they should be vertically crossed;

7.4 Avoid parallel laying with power lines and try to avoid large inductive electrical equipment;

7.5 Avoid areas prone to high temperatures and chemical pollution without damaging the shielding layer of the cable.

8. Requirements for fiber optic fusion and termination for fiber optic cable

8.1 The principle that optical fiber splicing should follow is: when the number of cores is equal, it should be connected to the corresponding colored optical fibers in the bundle tube. When the number of cores is different, the larger number of cores should be connected first, and then the smaller number of cores should be connected in sequence.

8.2 But in engineering, fusion welding is mostly used. The use of this fusion method results in low contact loss, high reflection loss, and high reliability.

Before fiber optic fusion, it is necessary to first prepare necessary operating equipment, tools, and materials such as fiber stripping pliers, cutting knives, fusion splicers, heat shrink sleeves, alcohol cotton, etc. to check whether the power supply of the fusion splicer is sufficient and whether all materials are complete. Then, remove the length of the optical fiber outer sheath, steel wire, and other optical fibers to be fusion spliced, and find the corresponding optical fibers that need to be fusion spliced. After making sufficient preparations in the early stage, prepare the end face according to the requirements The four steps of fiber fusion, fiber sorting, and quality inspection are carried out one by one.

9. Operation process of fiber optic fusion and fiber optic cable termination

9.1 The steps of fiber optic fusion include: fiber optic stripping, bare fiber cleaning, bare fiber cutting, fiber optic fusion,Fiber sorting and fiber testing.

9.2 Before fiber fusion, the fiber should be tested and comply with the provisions of the product technical documents;

9.3 Fiber optic fusion should be carried out in the order of fiber optic arrangement one by one and marked accordingly; When welding, the operation should be carried out according to the process methods specified in the product technical documents, and special equipment should be used for welding;

9.4 The optical fiber shall not be damaged or broken during the fiber fusion operation; The entire optical fiber fusion process should be completed continuously;

9.5 After fiber fusion, the fiber should be tested and comply with the provisions of the product technical documents; At the same time, keep records.

10. Precautions

10.1 The core of optical fiber is made of quartz glass, which is very easy to break. Therefore, it is never allowed to exceed the minimum bending radius during construction bending.

10.2 In order to meet the bending radius and tensile strength, the optical cable is usually wound on a reel during construction. In order to rotate the reel and pull out the optical cable, the reel can be installed on a dedicated bracket. The bending radius of the optical cable should be at least 15 times the outer diameter of the cable (referring to static bending, dynamic bending requires no less than 30 times).

10.3 Based on the situation of the optical cables transported to the construction site and in combination with the actual engineering situation, a reasonable combination of cable trays and cable laying sequence should be made, and the cable tray length should be fully utilized. During construction, it is advisable to lay the entire tray to reduce intermediate joints, and the optical cables should not be arbitrarily cut. The joint position of directly buried optical cables should be arranged in flat terrain and stable foundation areas.