A Best Francis Hydro Turbine Manufacturer in China since 1955

We are a top manufacturer of Francis Hydro Turbine in China.,

We are

- ISO 9001 Certificated Factory

- Over 70 years manufacturing Experience

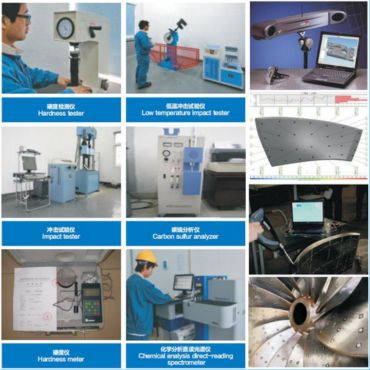

- World-class testing facilities for routine & type test

- Complete solution for your hydro power plant and its substation

What is a Francis Hydro Turbine

Francis Hydro Turbine was firstly invented by a British-American engineer, James B. Francis in 1848; Due to its highest efficiency for power generation, more & more clients are choosing Francis turbine for their hydro power plant.

PowerTel & his associated factory for manufacturing this Francis turbine with a single unit capacity less than 300 MW, established in 1955; Introduced and innovated Kvaerner Technology, own manufacturing facilities for Francis turbine and its generator; Over 70 years industry experience and its technical expertise made us have capabilities to provide you a complete solution for your hydro power plant, from its initial technical consulting, site survey, basic engineering design, optimal & construction design, supervision for construction & installation, testing & commissioning to final connection to lcoal power grid network.

Our Capabilities for Francis Hydro Turbine

Custom design & fabrication for Francis Hydro Turbines for any hydro power plant with a single unit capacity less than 300 MW. After we do geographic,topographic and climate survery on site, our expert engineers are able to provide you a value engineering design and choose a best type of Francis Turbine and its generator to fit your water head & flow to ensure a highest power generation efficiency for your power plant.

Over 50 years of experience in steel casting production. We have introduced & innovated world leading production equipment and process technologies such as German Magma casting simulation software, stainless steel precision metallurgy technology, and alkaline phenolic resin sand casting steel production line, with a single production capacity of up to 30 tons and an annual output of up to 10,000 tons.

it allowed us to do routine test & factory acceptance test under all kinds of environmental conditions,thus to assure a highest quality of our francis turbines. Pretest & pre-assembly before the shipment, making sure all components matched and connected perfectly & seamlessly. outstanding quality of our francis turbines made us rewarded an international reputation and thousands of hydro power plants installed around the world.

Except to provide an outstanding quality of francis turbines, through years of experience, we have innovated state-of-art software, which provides continuous supervision & control, covering the complete hydro power plant, thus will reduce your Operation & Maintenance costs, decrease failure risks, while ensuring a highest efficiency of power generation, safety & stability, further to increase revenues of your power plant and safeguarded your investment.

Main Features of Our Francis Hydro Turbine

The factory was established in 1955, which has nearly 70 years experience for manufacturing this francis turbine and its generator; Cooperated with our equipment manufacturers & research & academic institutions, we can provide you a complete solution for your hydro power plants, from its initial consultancy, basic engineering design, optimal & construction design, package supply of materials to operation & maintainance work.

Francis Hydro Turbines in Terms of Capacity

Product Feature Box

Over 60 years Casting Workshop

Our casting workshop tracked in 1955, which has over 60 years manufacturing experience for this Francis; it is a key manufacturing process for a highest quality of francis turbine and its generator.

In-house Testing Facilities

It allowed us to do all kinds of routine & acceptance test from raw materials to finished product; pre-assembly of some key components before each shipment, making sure all components can be connected perfectly and seamlessly, thus to assure an outstanding of each product before leav the factory.

Technical Support Through Lifecycle of the Products We Supplied

We understood, for a hydro power plant, any questions from our clients is urgent and very important; our expert engineers are always online to solve your problem, started from initial consultacy, basic engineering design, to future operation & maintainance for your hydro power plant.

Turnkey Solution for Your Hydro Power Plant & its Associated Substations

Through years of industry experience and technical expertise, we are able to provide you a turnkey solution for your hydro power plant and its electrical susbtations up to 750 kV.

Difference Between Francis Turbine & Kaplan Turbine

Francis turbine and Kaplan turbine are two main types of water turbine in terms of design and working principle, and their differences are as follows:

- Application of water head: Francis turbines working for water head ranging from 20 to 700 meters, while kaplan turbine is working in a much smaller water range from 5 to 50 meters. Francisturbines are suitable for situations with high water heads and are more sensitive to changes in the axial and radial velocities of water flow; The kaplan turbine is suitable for situations with lower water heads and requires higher radial velocity of water flow.

- Francis turbine normally has a bigger application range, more & more clients are choosing Francis turbine, due to its wide range and its efficiency of power generation.

- Different flow directions: The water flow of a Francisturbine has both axial and radial flow directions after entering the rotor. The radial and axial velocities of the water flow change after entering the rotor. However, the water flow of the kaplan turbine only has axial flow in the rotor, and the radial velocity of the water flow remains basically unchanged.

- Different rotor structures: The rotor of a francisturbine is composed of an impeller and guide vanes, and the water flow undergoes energy conversion between the impeller and guide vanes; The rotor of a kaplan turbine is composed of blades, and the water flow is converted into energy through the blades.

- Different pressure distribution at the impeller outlet: The pressure distribution at the impeller outlet of a francisturbine is relatively uniform, which is conducive to reducing the loss of water entering and exiting the impeller. The outlet pressure distribution of the impeller of the kaplan water turbine is relatively concentrated, and the flood discharge capacity is relatively strong.

Overall, there are significant differences between a francis turbine and a kaplan turbine in terms of flow mode, rotor structure, impeller outlet pressure distribution, and applicable range. Choosing the appropriate form of water turbine requires consideration of the specific engineering situation, local climate, geography & topography conditions and other technical requirements.

Please contact our expert engineers to guide you to choose a best type of water turbine for your hydro power plant.

Related Product

More information about this Francis Turbines

It consists of followings contents of its history Structure features, application arrange; key features of this turbine and its compositions.

An British-American Engineer Francis James B. improved a type of reactive water turbine in 1849 and in order to memorize this outstanding engineer, we called this new invented turbine, Francis turbine.

A Francis turbine is composed of diversion components, guide vanes, runners, and tailpipes. The water diversion component consists of a circular steel volute and fixed guide vanes, and the impeller is composed of an upper crown, a lower ring, and many twisted pieces fixed in between. The Francis turbine has a simple structure, reliable operation, high efficiency, and good anti cavitation performance. Suitable for medium head hydro power stations, more and more customers are choosing this water turbine due to highes efficiency of power generation.

The application of francis turbine has a wide range of water heads of 30-700m, a simple structure, reliable operation, and high efficiency. It is one of the most widely used water turbines in all kinds of hydro power plant.

The flow of water through the impeller is radial, and the outlet mechanism is radial. The opening of the guide vanes can be adjusted with the change of load. The impeller is composed of an upper crown, a lower ring, and a certain number of streamlined blades fixed in the middle. The introduction chamber is generally a metal volute or a concrete volute. The suction tube consists of a straight cone diffusion, a specially shaped elbow tube, and a diffusion section. The elbow section of a small unit is called a bent pipe, which is divided into different forms such as equal section and variable section.

The Francis turbine has a compact structure, high efficiency, and can adapt to a wide range of water heads. It is currently one of the widely used water turbine models in various countries around the world. When the water flows through the working wheel of this type of turbine, it enters radially and flows out axially, so it is also known as a radial axial flow turbine.

It is suitable for the range of water head from 30 meters to 700 meters, with a simple mechanism, stable operation, and high efficiency, but it is generally used in the medium water head range (50 meters to 400 meters). The single machine output ranges from tens of kilowatts to hundreds of thousands of kilowatts. At present, the maximum output of this type of water turbine has exceeded 700000 kilowatts. It is the most widely used type of water turbine. A 700 MW unit with a single unit capacity in China has been put into operation in the Three Gorges Dam, and an 800 MW mixed flow unit has been used in Xiangjiaba hydro power station.

The structure is simple, and the main components include volute, seat ring, water guide mechanism, top cover, runner, main shaft, guide bearing , bottom ring, draft tube, which also indicates the direction of water flow. A snail shell is a water diversion component, resembling a snail shell, usually made of metal material with a circular cross-section. The seat ring is placed between the volute and the guide vane, consisting of an upper ring, a lower ring, and several columns, and is directly connected to the volute; The column is wing shaped and cannot rotate, also known as a fixed guide vane. The water guide mechanism is composed of movable guide vanes, speed control rings, crank arms, connecting rods, and other components. The runner is directly connected to the main shaft (see turbine main shaft) and is the rotating component of this type of turbine. The runner is composed of an upper crown, a lower ring, a discharge cone, and several fixed blades. The shape and matching dimensions of each component vary depending on the water head used. The tailpipe is a water turbine discharge component that directs the water flow from the outlet of the turbine downstream. It is generally a curved elbow shape, and small turbines commonly use a straight conical tailpipe.