A Best Francis Turbine Manufacturer in China since 1955

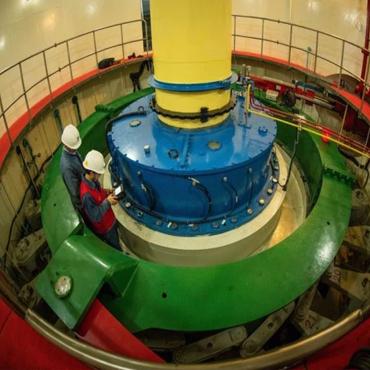

Being a professional manufacturer of Francis Turbine in China since 1955,

We are

- Over 70 years manufacturing Experience

- Thousands of Francis Turbine Supplied & Installed

- Technical Consultancy from its initial feasible study

- 24/7 online & on-site technical support till completion of your power plant

Francis Turbine

It has water in-take components, water guiding system, runner & impeller, and tailpipe. The water in-take system consists of a circular steel volute and fixed guide vanes, and the impeller is composed of an upper crown, a lower ring, and many twisted pieces fixed in between. Francis turbine has a simple structure, reliable operation, high efficiency, and good anti-cavitation performance. It is suitable for medium water head hydro power plants, which is the most widely used water turbine, with a water head range from 30 to 700 meters.

PowerTel & its associated factory is avaiable of this type francis turbine with a single unit up to 500 MW. Through years of industry experience and complete product chain, we are able to provide you a complete solution for your new or exisiting hydro power plant, from initial feasible study, value engineering design, supply of materials, installation supervision to final connection to local power grid network.

Main types of Hydro Turbine Generator

Hydro Turbine Generator Classcified by its Associated Water Turbine

Francis, Kaplan, Pelton

Hydro Turbine Generator Categoried by its Capacity

Product Feature Box

Our Manufacturing Facilities for Francis Turbines

Since 1955, we have worked with electrical utilities , new energy developers and EPC contractors around the world, thousands of hydro power plants used our water turbines.

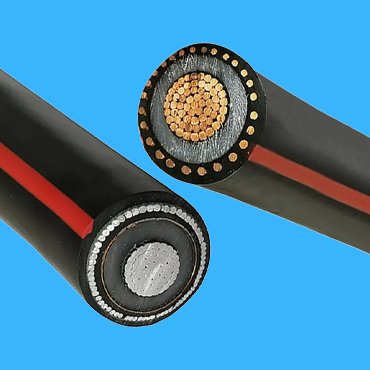

Complete Product Chain for Your Hydro Power Plant

Through complete product chain of hydro turbines, hydro power generators, and products for auxiliary system, for transmission & distribution lines, and its associated electrical substations, we are able to provide you a total solution for your new hydro power plant and rehabilitation of your existing hydro power plant.

24/7 Online Technical Consultancy and On-site Technical Support

Based on over 70 years industry experiece, our expert engineers can answer you any questions for your new or exsiting hydro power plant. They are able to provide you a custom & optimal engineering design for your power plant and help you to build or rehablitate your power plants at lowest possible costs while assure the highest possible efficiency, safety and stabilities.

Difference Between Brushed And Brushless Hydro Turbine Generator

Related Product

More introductions of Francis Turbine

Francis turbine is one of the most widely used water turbines arounfd the word .The water flows radially into the impeller and generally flows out along the axial direction. it has a wide range of water heads (30 to 700 meters), a simple structure, reliable operation, and high efficiency, has been chosen and used by more & more electrical utilities, new energy developers etc.

Structural characteristics of Francis Turbines

The flow of water through the impeller is radial, and the outlet mechanism is radial. The opening of the guide vanes can be adjusted with the change of load. The impeller is composed of an upper crown, a lower ring, and a certain number of streamlined blades fixed in the middle. The introduction chamber is generally a metal volute or a concrete volute. The suction tube consists of a straight cone diffusion, a specially shaped elbow tube, and a diffusion section. The elbow section of a small unit is called a bent pipe, which is divided into different forms such as equal section and variable section.

Francis turbine has a compact structure, high efficiency, and can adapt to a wide range of water heads. It is currently one of the widely used water turbine models in various countries around the world. When the water flows through the working wheel of this type of turbine, it enters radially and flows out axially, so it is also known as a radial axial flow turbine.

It is suitable for the range of water head from 30 meters to 700 meters, with a simple mechanism, stable operation, and high efficiency, but it is generally used in the medium water head range (50 meters to 400 meters). The single machine output ranges from tens of kilowatts to hundreds of thousands of kilowatts. At present, the maximum output of this type of water turbine has exceeded 700000 kilowatts. It is the most widely used type of water turbine. A 700 MW unit with a single unit capacity in China has been put into operation in the Three Gorges Dam, and an 800 MW Francis turbine has been adopted in Xiangjiaba Hydro Power Plant.

Components of a Francis Turbine

The structure of the francis turbine is simple, and the main components include the volute, seat ring, guide system, top cover, runner & impeller, main shaft, guide bearing , bottom ring, draft tube, etc., which also indicates the flow direction. A snail shell is a water diversion component, resembling a snail shell, usually made of metal material with a circular cross-section. The seat ring is placed between the volute and the guide vane, consisting of an upper ring, a lower ring, and several columns, and is directly connected to the volute; The column is wing shaped and cannot rotate, also known as a fixed guide vane. The water guide mechanism is composed of movable guide vanes, speed control rings, crank arms, connecting rods, and other components. The runner is directly connected to the main shaft and is the rotating component of this type of turbine. The runner is composed of an upper crown, a lower ring, a discharge cone, and several fixed blades. The shape and matching dimensions of each component vary depending on the water head used. The tailpipe is a water turbine discharge component that directs the water flow from the outlet of the turbine downstream. It is generally a curved elbow shape, and small turbines commonly use a straight conical tailpipe.