Your Reliable Supplier of Grounding Wire in China

Being a supplier of grounding wire over 20 years, we can provide you a full range of grounding wire, including

- Galvanized Steel Wire

- Aluminum Cladding Steel Wire

- Copper Cladding Steel Wire

- OPGW Cable

- And its Associated Hardware & Fittings

What is a Grounding Wire

There are many many types of grounding wires used in different electrical equipment & electrical syste. What we make & supply is used for power transmission & distributions lines. they are made of galvanized steel wire, Cu cladding steel wire and Al cladding steel wire. it is a safety cable to ensure power lines protected from lighting and other occasional electrical faults. this grounding wire provide an electrical path to the ground and divert the fault current into the ground, thus to assure the safety of power lines and people working on or near these power lines.

PowerTel & his factories can offer you a full range grounding wire and its related guy wire anchor or guy wire clamp for your varied applications. Please send us an email to us if you have any further questions about this product.

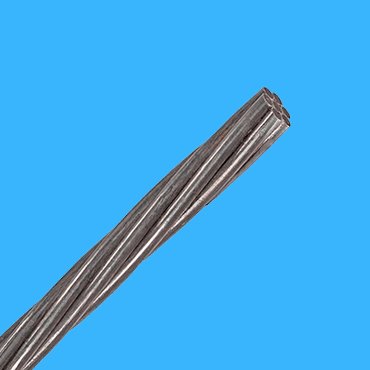

Grounding wire made of Galvanized Steel Wire

Due to the fact that the overhead ground wire does not bear the function of transmitting current, it is not required to have the same conductivity and cross-section as the wire. Generally, galvanized steel stranded wire is used for overhead grounding wire.

7 strands of galvanized steel wire

HS strength: 10,800 lbs

EHS strength: 15,400 lbs

Referring to ASTM A363 & 475

7 strands of galvanized steel wire

EHS strength: 40,200 lbs

Referring to ASTM A363 & 475

7 strands of galvanized steel wire

EHS strength: 26,900 lbs

Referring to ASTM A363 & 475

7 strands of galvanized steel wire

EHS strength: 20,800 lbs

Referring to ASTM A363 & 475

7 strands of galvanized steel wire

EHS strength: 6,650 lbs

Referring to ASTM A363 & 475

7 strands of galvanized steel wire

EHS strength: 11,200 lbs

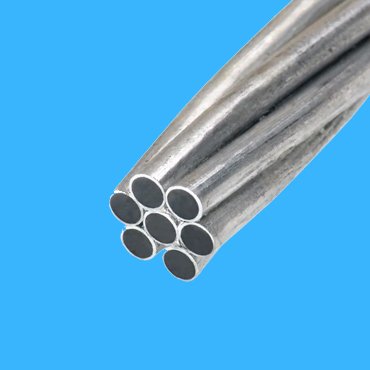

Grounding Wire Made of Al Cladding Steel Wire

Strandings from 3,7,19 to 37

Wire size from 4 to 12 AWG

Excellent Corrosion Resistance

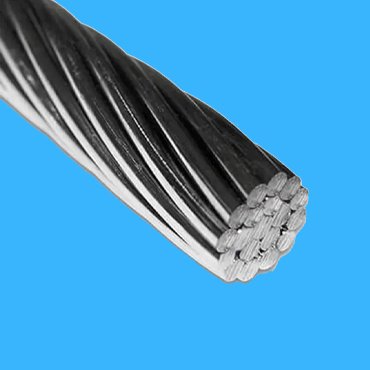

Grounding Wire by Standard of IEC 60888/BS183

According to IEC 60888/BS 183, there are over 50 types stranded galvanized steel wire used as an overhead ground wire. we can provide you the full range of this earth wire, her we only list six main types.

Product Feature Box

Self Innovated High-speed Galvanizing Production Line

Self Innovated High-speed Galvanizing Production Line Made us have an annual production capacity of Galvanized steel wire of 20,000 metric tons.

Premium Raw Materials We Used for Grounding Wire

We guarantee the highest product quality due to our use of high quality raw materials and precise manufacturing processes.

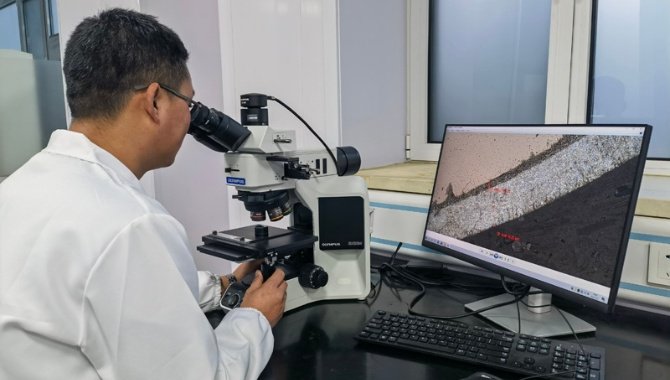

Stringent Test for Each Processing

Raw materials and semi-finished products will be tested and documented. Traceability records can trace every step from raw materials to finished products.

Related Product

What is a grounding wire used for?

For power transmission & distribution lines, it generally composed of foundations, towers, fittings, insulators, conductors, grounding wires (including OPGW optical cables), grounding facilities, and other components The power line erected above the overhead transmission line conductor to avoid direct lightning strikes on the transmission line conductor is both an overhead grounding wire (referred to as the grounding wire) and a lightning conductor. In addition to lightning protection, overhead grounding wires also play an important role in short-circuit current diversion. Overhead transmission lines are widely distributed, located in open fields, crisscrossing for hundreds of kilometers, and are prone to lightning strikes during thunderstorm seasons, causing power outages, becoming one of the main reasons for power outages in the power system. Installing overhead ground wires can reduce lightning accidents and improve the safety of line operation. The overhead ground wire is an important component of the structure of high-voltage transmission lines. High voltage, ultra-high voltage and ultra-high voltage substations cover a wide area and require a large area to prevent direct lightning strike. It will be difficult to install lightning rod, so sometimes overhead ground wires are also used for protection. Overhead ground wires are erected above the protected conductors. When lightning clouds discharge onto the ground above the line, the lightning flash channel is prone to first hit the overhead ground wire, causing lightning current to enter the ground to protect the normal power transmission of the wire. At the same time, the overhead ground wire also has an electromagnetic shielding effect. When lightning clouds near the line discharge the ground, it can reduce the lightning induced overvoltage caused on the wire and reduce the chance of lightning directly hitting the wire. The overhead grounding wire must be firmly connected to the tower grounding device to ensure that after being struck by lightning, the lightning current can be reliably introduced to the ground, reducing the tower top potential, and avoiding a sudden increase in lightning point potential that may cause a counterattack, thereby improving the lightning resistance level.

Functions of a grounding wire

Overhead grounding wires can effectively prevent direct lightning strikes on transmission lines; When lightning strikes the transmission line tower, the overhead grounding wire can play a diverting role, reduce the tower top potential, and prevent lightning from striking back; When lightning strikes the ground near the transmission line, the overhead grounding wire can play a shielding role, reducing the induced lightning overvoltage on the transmission line.

2.1 Prevention of lightning strikes on conductors

Reduced the chance of direct lightning strikes on the wire and reduced the amplitude of lightning overvoltage borne by the insulation of the line. When lightning strikes the tower top or ground wire, the tower body potential is very high, and the voltage applied to the insulator string is equal to the difference between the tower body potential and the wire potential. This voltage is generally much lower than the voltage on the insulator string when lightning directly strikes the wire, and will not cause flashover discharge. However, if the grounding resistance is high, the tower body potential will be high, and reverse flashover will occur

2.2 Lightning current diversion effect

When lightning strikes the top of the tower, the overhead ground wire has a shunt effect on the lightning current, reducing the lightning current flowing into the tower and reducing the potential at the top of the tower.

2.3 Coupling effect on wires

When lightning strikes the tower top or grounding wire, due to coupling, the potential of the wire will rise, so coupling can reduce the voltage on the insulator string. Therefore, in order to reduce “counterattack”, when it is difficult to reduce the grounding resistance, the shunt and coupling properties of overhead grounding wire can be used to add another coupling ground wire below the conductor.

2.4 Shielding effect on wires

Due to the grounding of the overhead ground wire, it can shield the conductor from induced lightning and reduce induced lightning overvoltage.

2.5 With communication function

The conventional overhead ground wire has been appropriately modified by placing the optical fiber on the double functional overhead ground wire made of aluminum clad steel wire twisted with ground wire and communication – the optical fiber composite overhead ground wire (OPGW), which has dual functions for lightning protection and communication.

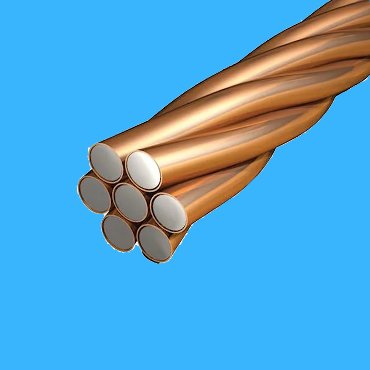

What Types of Grounding wire are there?

There are galvanized steel wire, Aluminum cladding steel wire, Copper cladding steel wire, and even OPGW cable.

Why Choose our Grounding Wire

- Large production capacity, a fast delivery time is guarantted.

- Premium raw materials, precise manufacturing process, plus strict testing procedures , assuring highest quality of grounding wire.

- Package supply with ground wire & its accessories.