Your Best Low Voltage Cable Supplier in China

Being a professional wire cable manufacturer over 20 years, we are able to design & manufacture a wide range of low voltage cable for your various application, also included cable gland, low voltage panels etc.

- ISO 9001 Certificated Company

- RoHS Compliant

- Worldwide Performance

- Individual Design to Fit your Custom Needs

What is a Low Voltage Cable

Low Voltage Cable, normally refers to an electrical cable voltage rated less than 1000 volts.

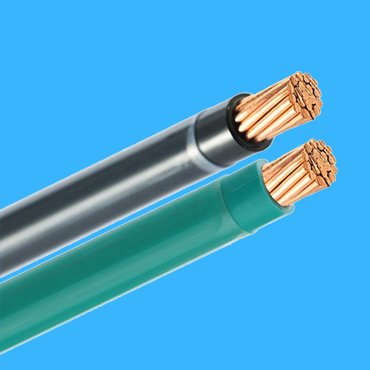

Through years of manufacturing experience, PowerTel & its associated factory can produce PVC or XLPE insulated cables, both armoured and unarmoured, with a phase–to–phase voltage of 1000 volts, including one with a reduced neutral conductor. The main conductor used is plain annealed copper, though other conductors such as tinned copper and aluminium is available upon your request.

Low Voltage Cable by ASTM,UL & ICEA Standard

8000 Al Alloy Wire

RHH/RHW-2 XLPE Insulated

XLPE Outer Jacket

8000 Al Alloy Wire

USE-2 XLPE Insulated

XLPE Outer Jacket

1350 Al wires

XLPE Insulated

XLPE Outer Jacket

1350 Al wires,range from 4 awg to 500 kcmil

XLPE Insulated

XLPE Outer Jacket

1350 Al wires,range from 6 awg to 1000 kcmil

XLPE Insulated & Outer Jacket

Annealed Cu Conductor

Insulated by FR-PVC with Nylon

Sheathed by UV PVC

Annealed Cu Conductor

Insulated by FR-PVC with Nylon

Sheathed by UV PVC

Annealed Cu Conductor UL 1277

Insulated by FR-XLPE

Sheathed by CSPE

Low Voltage Cable by IEC 60502-1

Product Feature Box

Global Manufacturing Facilities

We have an extensive global network of manufacturing facilities for Low voltage cable, offering us significant scale and flexibility to meet our customers’ needs for their different applications.

Indidivual Design and Solution

At our technical center, Our expert engineers work closely with customers to continually enhance their existing products and technologies, as well as create customized solutions that are tailored to the requirements of individual countries and industries for the requirement of low voltage cable.

Package Supply of Materials

Except a low voltage cable,we are dedicated to provide you its related products, like cable gland, LV panel, transformer, cable tie and even a bolt & nut, thus will save your time & costs a lot.

Difference between PVC & XLPE Insulated Low Voltage Cable

Both cables have a similar structure, conducotr, insulation,shield layer, armored layer and outer sheath, having good mechanical strength, bending performance, anti-corrosion performance, and a long service life; the main difference would be temperature resistance; for a PVC insulated cable, normal operation temperature is 70C,while for XLPE insulared low voltage cable is 90C; when short circuit happening, temperature would be 160C for 5 seconds, while be 250C for 5 seconds for an XLPE Insulated Low voltage cable.

Related Product

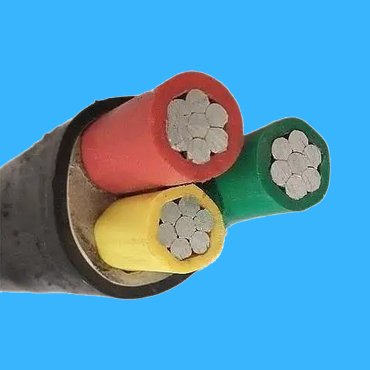

What components of a low voltage cable

It normally consists of conductor,(stranded or solid Aluminum & copper, Flexible Al or Cu conductor); Insulation (PVC, XLPE,XLPO,Rubber); Shield layer (copper wire or tape, Al-laminated tape); Inner Sheath (PVC,PE or Rubber) ; Armoring Layer (coper tape, galvanized steel wire); and Outer sheath (PVC, PE or XLPO);

Selection of a Low Voltage Cable

- Selection of cable conductor There are many types of conductors used for transmitting current, but there are usually two types of conductors used for low-voltage cables: aluminum and copper. At normal temperatures, the resistivity of aluminum is 1.68 times that of copper. At the same cross-sectional area, the current carrying capacity of copper wire is about 1.5 times that of aluminum wire. In terms of consumption, copper wire has lower consumption than aluminum wire. In terms of mechanical properties, copper wire has better performance than aluminum wire, and its fatigue strength is about 1.7 times that of aluminum wire. In terms of specific gravity, the quality of aluminum wire is about half that of copper wire. Aluminum conductors are mostly suitable for environments that corrode copper, overhead lines, and medium frequency lines with larger cross-sections. Except for situations where aluminum conductors are suitable, copper conductors should be chosen as much as possible.

- The number of cable cores in a low voltage cable mainly depends on the voltage and grounding method. 2-core cables are generally used for 220V, 3-core cables are generally used for 380V400V, and 4-core cables are generally used for cables with N 380V-400V, 5-core cables are generally used for 380V-400V with N and PE wires. While saving costs and not reducing safety, the cross-sectional area of N and PE lines is generally about half of the phase line. In special occasions such as hospitals and mines, the cross-sectional area of N line and PE line is the same as that of the phase line.

3. Insulation materials

(1) Cable insulation materials used in general situations

① Long term tolerance for PVC insulated cables

The allowable working temperature is 70 ℃, and the allowable temperature for short-circuit thermal stability is 160 ℃. However, its disadvantage is poor adaptability to the environment, and it will accelerate aging beyond -15 ℃ and 60 ℃.

② Long term allowed for cross-linked polyethylene insulated (XLPE) cables

The working temperature is 90 ℃, and the allowable temperature for short-circuit thermal stability is 250 ℃. This insulated cable has the characteristics of excellent performance, simple structure, light weight, large current carrying capacity, and milk corrosion The long-term allowable working temperature for rubber insulated cables is 60 ℃, and the allowable temperature for short-circuit thermal stability is 200 ℃. Ordinary rubber insulated cables are prone to corrosion and poor heat resistance when encountering oils and their compounds. It is recommended to use ethylene propylene rubber insulation (EPR), which has a long-term allowable working temperature of 90 ℃ and a short-circuit thermal stability allowable temperature of 250 ℃. It has excellent electrical and mechanical properties, and has characteristics such as oil resistance, ozone resistance, weathering resistance, and high temperature resistance.

(2) Flame-retardant electricity should be used in places with special fire protection requirements Cable.Flame retardant cable refers to a cable that, after being burned, has spread the flame within the specified range, remove the ignition source, and the flame can extinguish itself within a specified time.

Flame retardant materials for cables. it generally divided into two categories: halogenated and halogen-free: halogenated type with resistance;Good combustion performance, low price, thick smoke during combustion, acid mist, and Features such as high toxic gas, materials such as polyvinyl chloride and polytetrafluoroethylene Ethylene, polysulfonated polyethylene, chloroprene rubber, etc; Halogen free tools Low smoke, low toxicity, no acid mist, poor flame retardancy, and materials ; There are polyethylene, cross-linked polyethylene, natural rubber, and ethylene propylene rubber, silicone rubber, etc.

Fire resistant cable refers to a cable that, under specified experimental conditions, Capable of maintaining normal operating characteristics after prolonged combustion in flames for a certain period of time; Classified into Class A based on fire resistance characteristics (fire resistance temperature 900-1000 ℃) and Class B (fire resistance temperature 750-800 ℃), during fire supply, The interval is 90mm. According to insulation materials, it can be divided into organic and inorganic type: Some models use high-temperature resistant mica tape of 800 ℃ as a fire resistance layer; The drone uses magnesium oxide as insulation material, allowing for long-term normal operation at a high temperature of 250 ℃.

(2) Selection of cable cross-section

The selection of cable cross-section has the following considerations:

The cable cross-section is mainly calculated based on the current of the load and

The selection should be based on the current carrying capacity of the cable, and on this basis, the following factors should be taken into consideration in order to consider the overall and long-term perspective.

Choosing the appropriate cross-section of a low voltage cable is also very important :

1. Cable temperature rise

When the low voltage cable is working, it will pass through due to the environment and current and heating, therefore the worst working environment temperature of the cable

It is not allowed to exceed its allowable value and the long-term working current;

The cable current carrying capacity published by authoritative departments should not be exceeded.

2. Economic current

Select an exact type of low voltage cable based on current carrying capacity, not only considers the initial investment, but also considered the loss of conductors during their lifespan. When the initial investment only considers the current used by the load, but after a certain period of time; The line may suffer from wear and tear, which will result in expenses. Therefore, according to the the concept of economic current, initial investment, and line losses are considered; After consideration, the cable cross-section was increased, resulting in an increase in initial investment; The cost of line loss has been reduced. In these two intervals, the total economic cross-section is the one with the least cost.

The principle of selecting wires and cables based on economic current (IEC),

Established the standard of “optimizing the core cross-section of power cables”

(IEC287-3-2/1995)。

3. Voltage loss

Due to the inherent resistance of the cable, during operation, the voltage is inevitably affected to a certain extent, and the longer the cable length, the longer the resistance value, the greater the voltage loss, resulting in.The actual voltage deviation of the backup terminal from the rated voltage will affect the performance of the equipment

Affected, even unable to run. Therefore, when selecting a low voltage cable,the cable cross-section should be appropriately increased according to the length of the cable.

4. Protective measures

When selecting a low voltage cable, protective components should also be considered,

If there is a fault in the line or load end, and the protection component, If it has not yet taken effect, the cable will be damaged, which means the rated current of the protective element must be less than the current carrying capacity of the cable. Otherwise, the cable cannot be protected.

In addition, the longer the cable, the more it will affect the protection components

sensitivity, as the length of the cable is related to its own impedance, therefore the cable cross-section should also increase as the cable length increases.

5. Mechanical strength

In conclusion, the selection of a low voltage cable should take into account not only the current–carrying capacity, but also the application requirements, voltage drop, mechanical strength, as well as economic factors. An appropriate selection method can result in higher economic and social benefits to buil up your low voltage electrical system at lowest possible costs while assuring a smooth & safe operation.