Your Best Medium Voltage Cable Supplier in China

Being a professional medium voltage cable manufacturer over 30 years, we are able to provide you a full range of the cables and

- Cold Shrinkable Cable Joint

- Hot Shrinkable Cable Joint

- Straight Cable Joint

- A Custom Design & Fabrication for the Cable

What is a Medium Voltage Cable

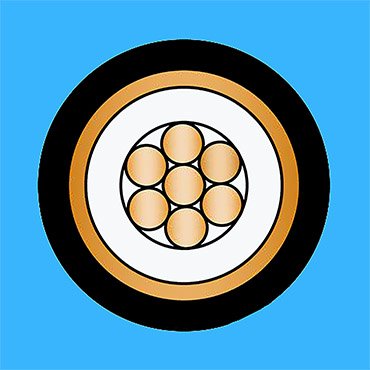

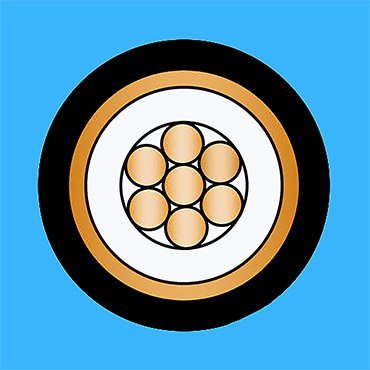

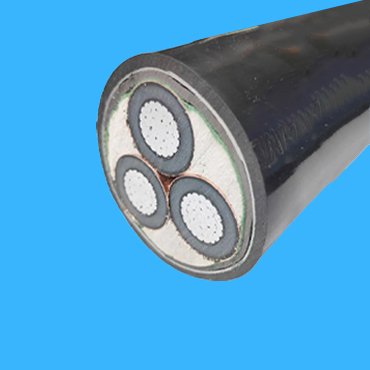

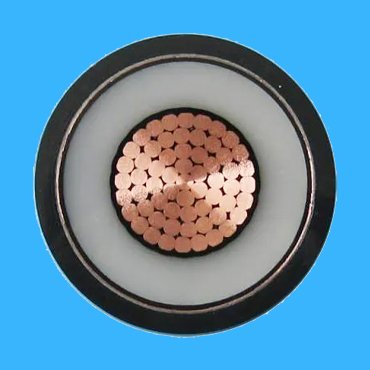

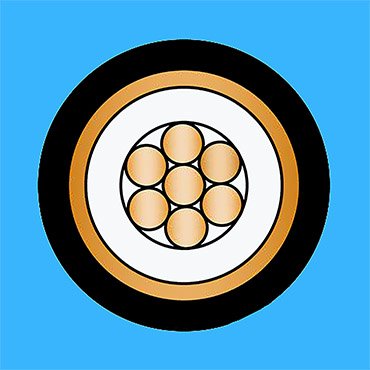

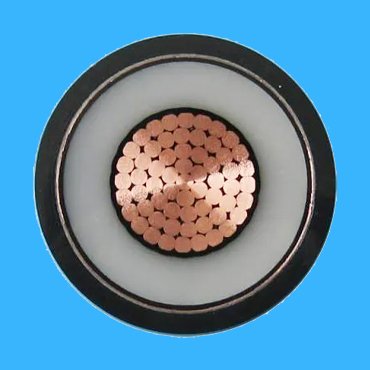

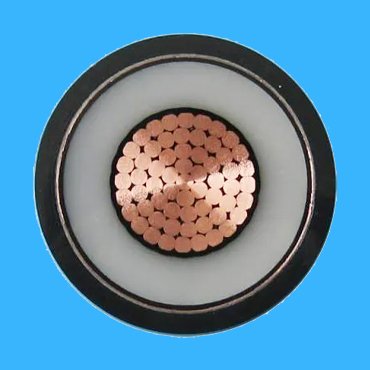

Medium Voltage Cable, referring to the voltage level rated from 1 kV to 35 kV, Single or three core Copper or Aluminum Conductor, Insulated by PVC, XLPE or EPR, Shielded by copper wire or tape and armored by copper wire or galvanized steel wire and finally sheathed by PVC, PE or rated in flame retartant or fire resistance.

PowerTel & its associated factory can provide you a wide variety of this medium voltage cable and its accessories. Meanwhile, our dedicated can work closely with you to offer a tailored design of the cable for your special needs.

Medium Voltage Cable by ASTM,UL,ICEA & AEIC Standard

Al or Cu Conductor

100% or 133% Insulation Level

EPR or XLPE Insulated

Cu or AL conductor, range from 1 awg to 1000 kcmil

Insulated by EPR & Sheathed by PVC or LSZH

1/C or 3/C Cu or AL

EPR or XLPE Insuation with 100% or 133 level

PVC or LLDPE Jakceted

1/C or 3/C Cu or AL

EPR or TR-XLPE Insuation with 100% or 133 level

PVC or LLDPE Jakceted

AL or Cu conductor

EPR or TR-XLPE Insuation with 100% or 133 level

PVC or LLDPE Jakceted

Medium Voltage Cable by IEC 60502

Medium Voltage Cable by BS 6622 & 7835

Product Feature Box

Triple-Extrusion Production Line for Medium Voltage Cables

Conductor shielding, insulation, and semi conductive insulation shielding are extruded in a triple extrusion equipment to ensure the degree of cable insulation purification and the quality of our medium voltage cables.

Eccentricity Testing for Medium Voltage Cable

To ensure the highest quality of our medium voltage cables, we would implement stringent testing at each stage of the manufacturing process.

Advanced ERP & MES Management

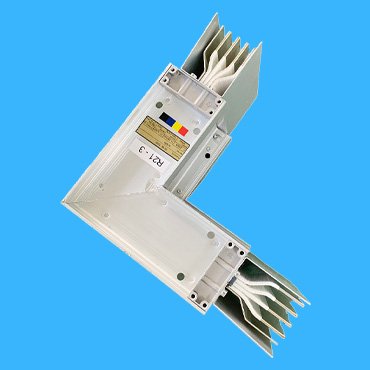

Related Product

Steps for partial discharge withstand voltage test for medium voltage cable

1. Turn off the main power switch and the control power switch.

2. Confirm that the shield room door is closed and the system is in a powered on state.

3. Select appropriate reactors and high-voltage taps based on the length and cross-section of the medium voltage cable. When the electric switching tap switch inside the reactor is in the fully rated (current) state, the buzzer should stop sounding, indicating that the high-voltage tap is ready.

4. Select the appropriate voltage measurement range.

5. Check the ‘tuning speed’ and adjust it to approximately 30% of the maximum value.

6. Connect the main circuit of the high-voltage power supply.

7. Step up the voltage to increase the output voltage of the excitation transformer to 1% of the required test voltage value. For example, if the test voltage is 10KV, the output voltage of the excitation transformer is 0.1KV.

8. At this excitation voltage, adjust the gap position of the high-voltage reactor to achieve resonance in the test circuit. Attention should be paid to the high-voltage output voltage. When the output value reaches its maximum, it indicates that the circuit has reached a resonant state.

9. When the test circuit is in a resonant state, press the “boost” button again to increase the output voltage to the test voltage value.

10. When the test time is up, press the “Step Down” button to reduce the output voltage to the minimum value, and then press the “High Voltage Split” button to cut off the high-voltage power supply of the circuit in the test system. Attention: Do not directly press the “High Voltage Separation” button under high test voltage to prevent breakdown of the test object.

11. After the test is completed, disconnect the “air switch” on the voltage regulator, and if necessary, disconnect the incoming switch of the entire equipment current to ensure the safety of operators. Preparation before the test: Strip the cable head: 1) Strip the semiconductor shield (10kV) with a length of 100-150mm, and (35kV) with a length of 500-700mm; Requirement: The peeling cut should be smooth and no sharp points are allowed. 2) The stripping length of the shielding copper strip is about 100mm longer than that of the semiconductor shielding. 3) The armored steel strip should be cut flat and cleaned. Preparation of transformer oil (freon): filter, dry, and the breakdown field strength shall be above 40KV. Attention: 1. During the experiment, it is not allowed to open the doors and windows of the operating room at will. At this time, if there is a discharge, there will be a phenomenon of electricity filtering, leading to misleading data. 2. Both ends of the test cable should be immersed in an oil cup. The high voltage introduced to the cable is called a near oil cup, and there are elastic copper needles inside the oil cup. The other short is the far oil cup, which has no elastic copper needle. 3. The oil should be soaked through the semiconductor shield for about 5-10mm to avoid discharge, and the end of the cable at the far end of the oil cup should be about 10mm away from the bottom of the oil cup.

Key technical properties of a medium voltage cable

1.Insulation eccentricity

The eccentricity of insulation after three-layer co extrusion shall not exceed 10%.

2. Cable routine partial discharge test

At 1.73Uo, there were no detectable discharges generated by the tested cable that exceeded the declared test sensitivity (6pC or better).

3. Cross linked polyethylene insulation shrinkage test

Processing conditions: The length L between signs is 200mm; Processing temperature 130 ± 3 ℃; Duration: 1 hour. The maximum shrinkage rate of cross-linked polyethylene insulation shall not exceed 2%.

4. Cross linked polyethylene insulation thermal extension test

Processing conditions: Air temperature 200 ± 3 ℃; Load time 15 minutes; Mechanical stress 20N/cm2. The maximum elongation of cross-linked polyethylene insulation under load shall not exceed 130%.

5. Insulation tg δ

Rated voltage 12/20kV cable insulation tg δ Value not greater than 40 × 10-4

6. 4h voltage test

Apply a voltage of 4Uo/4h without breakdown of the medium voltage cable.

7. Cross linked polyethylene insulation thermal extension test

Processing conditions: processing temperature 200 ± 3 ℃; Load time 15 minutes; Mechanical stress 20N/cm2. The maximum elongation of cross-linked polyethylene insulation under load shall not exceed 130%.

8. External semi conductive layer peeling test

9. Isolation sleeve power frequency withstand voltage

Apply 15kV/1min , no breakdown of a medium voltage cable.

Some introductions of cold shrinkable terminal joint for a medium voltage cable

The technological progress of medium voltage cable accessories is actually accompanied by the gradual development of cable technology, it has three main types cable accessories for a medium voltage cable; they are hot shrinkable, pre-moulded and cold shrinkable terminal jointand the cold shrink cable joint is currently the most advanced and widely used for medium voltage cable.

Cold shrink cable joints effectively compensate for some of the shortcomings of heat shrink and pre-moulded cable joint, while also possessing some of the technical characteristics of both, such as on-site shrinkage installation of heat shrink cable accessories and the applicability of one model product to multiple wire diameter cables; Pre-moulded cable joint has a multi-layer structure that is prefabricated as a whole, and the installation of the multi-layer structure is completed simultaneously, avoiding layering and internal air gaps. what is more, there are also some other advantages of a cold shrink cable joint for medium voltage cable.

1. No need for hot work, no need for special tools, unrestricted usage, and no safety hazards during on-site construction

2. The installation is simple and does not require special training. Generally, construction personnel can complete the installation task after simple training

3. The attachment contains several layers of structure, which can be installed in one go without the need for layered installation, simplifying the installation process and ensuring installation quality.