Your Best Supplier of Medium Voltage Switchgear in China with Custom Design

As a professional medium voltage switchgear supplier over 20 years, we can provide you a wide range of electrical switchgear rated from 3.6 to 40.5 kV , a custom MV switchgear for your special needs, and a package supply of distribution transformer, MV power cable or electrical busway, make you a seamless connection of your electrical distribution system.

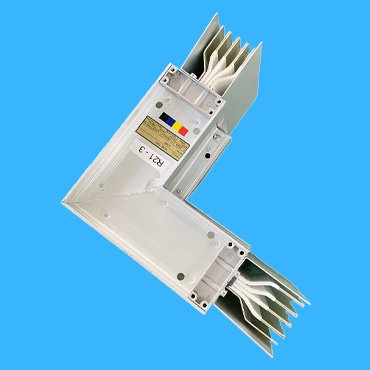

What is a Medium Voltage Switchgear

Medium voltage switchgear refers to an electrical switchgear with a voltage level of 3.6-40.5kV, At present, it has two main categories: handcart type and fixed type. Fixed switchgear refers to the fixed installation of main primary components (such as circuit breakers, isolation switches, etc.), while handcart type refers to the movable circuit breakers and other main components. According to the cabinet structure, it can also be divided into metal enclosed armor type, metal enclosed interval type, and metal enclosed box type structures. Armored type: all busbar rooms, circuit breaker rooms, cable rooms, and instrument rooms are isolated with grounded metal sealing plates, ensuring good safety; Bay type: that is, the circuit breaker compartment or other compartments are sealed with insulation boards, followed by safety;

PowerTel & its associated factory can offer you a wide range of medium voltage switchgear for different applications; Our experienced & dedicated engineers will work closely with you to offer a tailored design and fully comply with your local regulations and requirement of your whole electrical system, assuring the whole system running smoothly, safely and stably.

Medium Voltage Switchgear

Equipped with vacuum circuit breaker, up to 100 kA breaking capacity; Equipped with three-position disconnector

Referring to GB/DL, CSA, IEC & IEEE standard; Plug-in voltage transformer-both feeder & Cu busbar

Pre-assembled with one fuse switch; Rated current up to 630A, up to 24 kV power distribution system;

Referring to IEC 62271; Assembled with 1 to 3 cable switch and over 10 vacuum breakers; up to 25 KA breaking capacity

Voltage Rated 12/17.5 kV; up to 65 kA breaking capacity; equppied with IEC 61850 digital communication system

Compact design to save your installtion space; Rated current up to 1250 A & 30 kA for its breaking capacity

Product Feature Box

Highest Quality of Medium Voltage Switchgear

We fully understood that quality of a medium voltage switchgear is crucially importance for an electrical distribution system; We promoted the principle of excellence and perfection, executed a thorough quality management system, and strived to improve the quality of products, management standards, and overall business performance.

Comprehensive Solutions to your Power Distribution System

Except a tailored medium voltage switchgear, in the field of electrical equipment, we can provide customers with AIS & GIS switchgear below 220kV, medium and low voltage complete electrical equipment, intelligent components, copper bus & electrical busway, transformers, power system automation and system integration; Provide customers with solutions including new energy generation systems, intelligent substation systems, distribution automation systems, factory automation, and energy efficiency management systems

24/7 Technical Support & Service

Our around-the-clock technical support started from your initial design of your project and end to on-site installation & training and daily operation & maintainance.

Related Product

Special Design for a medium voltage switchgear of high current

When the current of a medium voltage switchgear is ≥ 3000A, the magnetic flux generated by the energized conductor will significantly increase, and the eddy current generated by the alternating magnetic flux passing through the metal structural components around the conductor will also increase. The electromagnetic force generated by the eddy current will also continue to increase. In an environment with a current frequency of 50Hz, the eddy current will continuously change the direction of the current, and the direction of the electromagnetic force, i.e. the electric force, will follow the direction of the eddy current, The metal structural components that generate eddy currents vibrate under the action of electrodynamic forces, resulting in significant noise.

The vibration amplitude of metal structural components during vibration depends on the magnitude of eddy current, usually ranging from tens to hundreds of um. The vibration amplitude is also related to the area of the metal structural component. The larger the area, the greater the vibration amplitude and the greater the noise.

The impact of eddy current on metal structural components can be reduced through the following points:

① Fix the middle partition of the contact box with stainless steel material instead of the original aluminum zinc coated steel plate;

② Replace the ordinary steel rivets used for fixing the guide plate and frame of the metal valve with stainless steel rivets;

③ When the rated current is ≥ 3150 and 4000A, the metal valve adopts stainless steel without ferromagnetic materials;

④ When the rated current is ≥ 5000A, the top cover plates of the busbar compartment and high-voltage compartment are made of steel, and the busbar bracket is also made of stainless steel.

⑤ For the hexahedral frame of the switchgear, three faces are made of stainless steel material, and the closed magnetic circuits of the six face frame are all disconnected.

Type testing items for a medium voltage switchgear:

1. Insulation test;

(1) Power frequency withstand voltage (2) Lightning impulse withstand voltage

(3) Partial discharge test (4) Leakage current test

(5) Aging test

2. Main circuit resistance measurement and temperature rise test;

3. Peak withstand current and short-term withstand current tests;

4. Making and breaking capacity test;

5. Mechanical tests;

6. Inspection of protection level;

7. Operational vibration test;

8. Internal fault test;

9. Inspection of gas leakage rate and water content of SF6 gas insulated switchgear.

Factory Acceptance Testing Items for a medium voltage switchgear

1. Power frequency withstand voltage test of the main circuit;

2. Power frequency withstand voltage test of auxiliary circuit and control circuit;

3. Partial discharge measurement;

4. Measure the resistance of the main circuit;

5. Tests on mechanical performance, mechanical operation, and the function of mechanical anti misoperation devices or electrical interlocking devices;

6. Calibration and wiring correctness verification of instruments and relay components;

7. Inspection of SF6 circuit breaker leakage rate and water content;

8. Components with the same rating and structure that can be interchanged in use should be tested for interchangeability.

Technical Development Trends of Medium Voltage Switchgear

1. The modern production line, based on CNC sheet metal processing equipment and adopting an assembled structure, has greatly improved processing accuracy, appearance, protection level, and production efficiency.

2. The switch components are basically equipped with vacuum switches and a small amount of SF6 switches, greatly improving the breaking capacity and electrical life indicators. Laying the foundation for free maintenance of a medium voltage switchgear.

3. The miniaturization of switch components, various composite insulation structures, and the use of fixed sealing poles enable the miniaturization of switch cabinet products.

4. The improvement of insulation material performance and casting process significantly improves the internal quality and appearance level of insulation components.

5. Advanced surface coating technology and corresponding pre-treatment processes, such as electrostatic spraying and vulcanization coating, are widely adopted, greatly improving the rust resistance and appearance quality of products.

The combination of gas insulation technology and switchgear technology has promoted the development of medium voltage gas insulated switchgear, which has been successfully developed and dragged into mass production.

The development of modern sensing technology, digital technology, and communication technology has led to the widespread application of digital relays or control and protection devices, and the development of switchgear products towards digitization and intelligence.

Improving production quality and product reliability is a systematic project, and currently, it is necessary to pay attention to the primary concern of power transmission and distribution engineering to ensure safe and reliable power supply. From the perspective of the manufacturing plant, the focus of work should be on improving product reliability. Continuously investing manpower, material resources, and financial resources to improve design, making it more reasonable and advanced, and improving product performance is only one aspect of improving reliability. The improvement and stability of the process are very important aspects for improving product quality.