A High Quality OPGW Cable Manufacturer in China since 2000

As a professional OPGW cable manufacturer over 20 years, we are able to provide you a full range of OPGW cable and custom OPGW , which is equivalant to the OPGW proposed by AFL. PRYSMIAN, TAIHAN, SFPOC and ZTT etc.

What is an OPGW

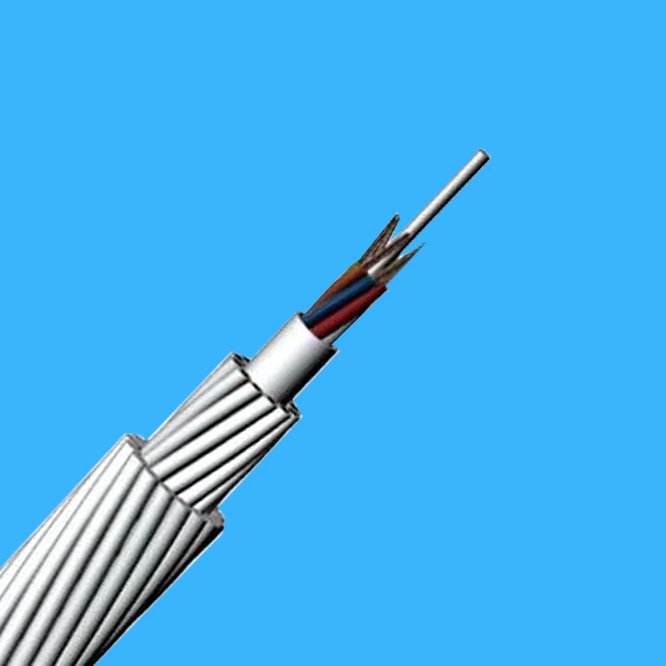

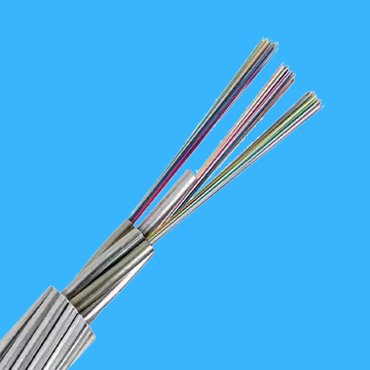

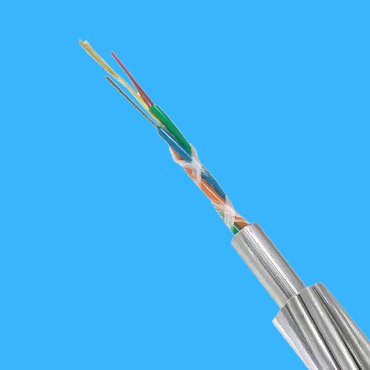

OPGW, is short for optical ground wires, which consists of an optical unit housing 12 to 288 G.652D or G.655 fibers and stranded together with some electrical wires such as aluminum wire, aluminum alloy wire, or aluminum cladding steel wire (ACS). This combination of features makes an OPGW capable of performing both grounding and fiber optic telecommunications, which is an ideal substitute for a traditional earth wire.

PowerTel & its factory have an annual production capacity of 50,000 km of a complete range of OPGW and tailored OPGW to match your grounding wire on power transmission lines. What is more, full range of hardware for OPGW is available here; we can provide you a package supply of OPGW & its accessories. through over 20 manufacturing experience for OPGW, we can help you to select a proper type OPGW in the initial design of a power transmission project, pls-cadd sag calculation, on-site technical support for installation OPGW & its hardware, fiber splicing and final testing.

Three Main Types OPGW

Aluminum Tube OPGW, Stainless Steel Tube OPGW and Al-cladding Stainless Steel Tube OPGW

Excellent anti-corrision & lighting performance; fault current has only a minor effect on the transmission properties of fibers.

More electrical wires used in this type OPGW cable, makes you have more options for your project. Larger cable diameters and more fibers, up to 144. Greater tensile strength and higher short circuit current capacity.

Increased the aluminum section, having a better fault current and anti-lightning performance. Suitable for transmission lines requiring an OPGW in a smaller diameter and larger short circuit capacity.

Product Feature Box

Annual Production Capacity, 30,000 KM

Six production lines, allowing us to have an annual production capacity of 30,000 km for all types of OPGW, a fast delivery time is assured here.

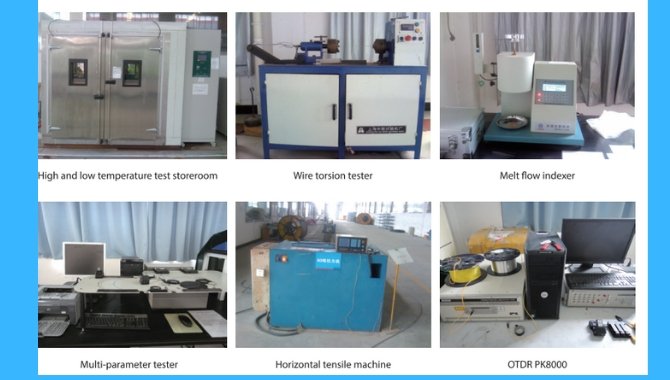

Well-equipped Testing Facilities

Our well-equipped testing facility supports the realization of high-quality OPGW and assists in the development and research of new OPGW.

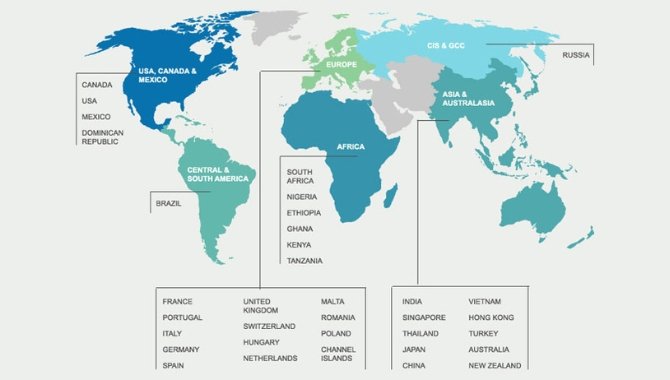

Worldwide Sale Reference for OPGW

India, over 4,000 km; Poland & Germany, over 1,000 km; Ethiopia, over 2,000 km; Peru & Chile, over 1,000 km; and North Americans, over 1,000 miles.

Type TesT Report Issued by Third Parties

Our OPGW has already been tested by Kinectrics in Canada and CEPRI in China, etc. and obtained the corresponding type approval reports.

Custom OPGW to Fit Your Special Requirement

Our expert engineers are ready to make a new & custom design of OPGW based on your technical drawings or a totally new OPGW based on mechnical & technical requirement of your power transmission lines.

Related Product

What is an OPGW used for

OPGW, is also known as Optical Ground Wire, installed on one side on the top of an electrical tower; an optical unit housing some optical fibers and stranded with some aluminum wires, aluminum alloy wires or aluminum cladding steel wires; it is used for a grounding wire and for optical telecommunication.

What types of fiber is used in an OPGW ?

Most customers choose to use single mode G.652D fiber and very few clients choose to use G.655 fiber.

What are the different types of OPGW ?

In terms of materials used for the optical unit, it can be divided into three main types of OPGW . they are aluminum tube OPGW cable, aluminum cladding stainless steel tube OPGW cable and stainless steel tube OPGW ; it is in a central or stranding form designed & manufactured, according to the requirement of each customer.

Key features of a stainless steel tube OPGW :

In a central form, it is small in cable diameter and light in weight, which is used to replace an old grounding wire; in a stranding form, it can be stranded in double or triple layers with a perfect combination of different electrical wires to suit different requirement of its electrical & mechanical performance. Fiber count is available up to 144.

Advantages of aluminum cladding stainless steel tube OPGW cable

It is normally in a central form; it has more aluminum conductor in the cable, which has a better performance for fault current, lighting resistance and corrosion resistance. It is widely used on some power transmission lines, which required the cable in a small weight and large fault current.

Main features of an aluminum tube OPGW cable

It is also in a central form; the material and structure of this type OPGW cable are uniform and have excellent vibration fatigue resistance. It also has excellent anti-corrosion and anti-lightning performance, and it has minimal impact on the optical fiber transmission property when there is a short circuit occurred.

What is the difference between OPGW and ADSS fiber optic cable?

- Materials are different

OPGW cable is stranded by conductive wires while ADSS cable is all made of dielectric materials, like FRP, strengthened by aramid yarn, fillers and PE outer sheath.

- installed in different positions & locations

OPGW cable only installed on the top of an electrical tower, while ADSS cable installed in the middle or in a lower level of an electrical tower and electrical poles etc.

- Functions are different

OPGW cable has double function for both earthing wire and optical communication and ADSS cable is only for optical telecommunication.

Our capacities for OPGW

Based on our manufacturing experience for OPGW cable over 20 years, we have capacities to provide you a full range of OPGW cable and tailored OPGW cable, which is equivalent to AFL OPGW cat # AC-86/646, AC-58/68/729, AC-74/552, CC-57/465, AC-34/52/646, AC-74/552,etc.

Meanwhile, full range of hardware for OPGW cable is available here; we can offer you a package supply of OPGW cable & its associated hardware, plus installation guide and technical support on your jobsite, fiber splicing, final testing & commissioning of the OPGW cable we supplied.