Your Best Power Cable Supplier in China

As a professional power cable manufacturer over 20 years, We introduced advanced cable manufacturing and testing equipment from the United States, Germany, the United Kingdom, and its self-innovated production lines. We specialized in the production of 500kV and below cross–linked cables, low & medium voltage cables, special cables, and building wires.

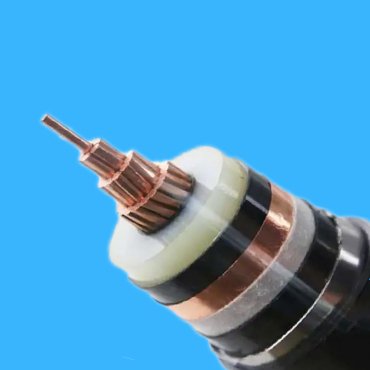

What is a Power Cable

When we talk about the power cables, it has a wide range of varieties of them; In this page, we will focuc on the power cables used on underground power transmission projects and aerial or duct installed low & medium voltage power cable to transmit the electrical energy between two electrical substations or distribute power resource to various loads in home daily use or for industrial & commercial applications.

Normally, Low voltage cables are commonly with voltages less than 1 kV. Medium voltage cables are in a voltage range between 1 kV and 35 kV. High voltage cables are used for long-distance, high-capacity power transmission, with voltages up to 110 kV or even higher.

PowerTel & its associated factories can provide you a full range power cable with the voltage level up to 500 kV, together with its cable terminal kit, cable straight joint and other accessories.

Power Cable by its Voltage Level

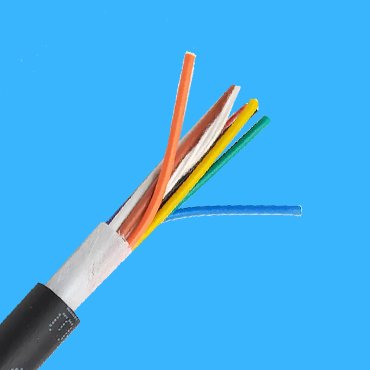

According to its voltage level, it can be divided into low voltage cable, medium voltage cable, high voltage cable and even extra high voltage. also in Armored or Unarmored power cable; XLPE insulated power cable or PVC insulated power cable etc.

PowerTel & its associated factories can provide almost a full range of power cable and its cable gland/joints or cable termiantion. Please send your cable datasheet or drawings, we will propose our design & its quote.

Conductor in pairs or in triads

Individual and/or overall shielded

Insulated by PVC or XLPE

Sheathed by PVC or LSZH

Conductor in pairs or in triads

Individual and/or overall shielded

Insulated by FR-EPR or XLPE

Sheathed by PVC or CPE

Annealed Cu conductor

Insulated by PVC or XLPE

Sheathed by PVC or LSZH

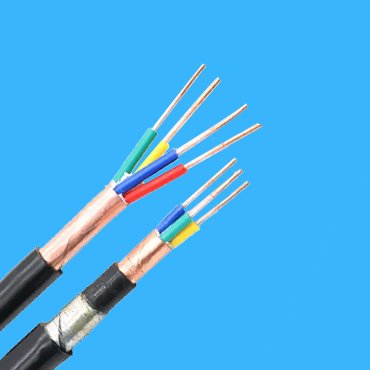

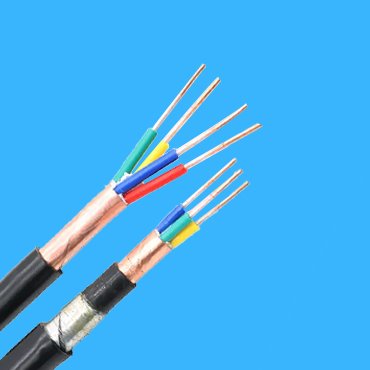

Single or three Al or Cu Conductor

Insulated by PVC or XLPE

Sheathed by PVC,PE or LSZH

Single or three Al or Cu Conductor

Insulated by PVC or XLPE

Sheathed by PVC,PE or LSZH

Al or Cu Conductor to IEC 60228

Insulated by PVC,XLPE or EPR

Sheathed by PVC,PE or LSZH

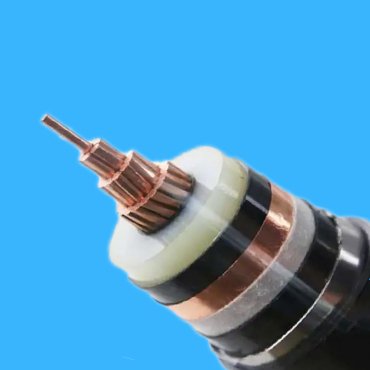

Al or Cu Conductor to IEC 60228

Insulation shielded by a non metallic or semi-conducting material

Sheathed by PVC,PE or LSZH

Al or Cu Conductor to IEC 60228

Metallic layer by Cu tape or wires

Inner lead sheathed & HDPE outer sheath

Al or Cu Conductor to IEC 60228

Armored by Al wires

Inner lead sheathed & HDPE outer sheath

Al or Cu Conductor to IEC 60228

Insulated by PVC,XLPE or EPR

Inner lead sheathed & HDPE outer sheath

Stranded Al or Cu Conductor

Insulated by XLPE

Sheathed by HDPE

Stranded Al or Cu Conductor

Seperation sheathed by Al tape

Sheathed by HDPE

Power Cable by Different Standard

Product Feature Box

State of the Art Manufacturing Facility

Well Equipped Testing Facilities

Well-equipped testing equipment is the guarantte of highest quality of our power cables, and enabling us to design and manufacture new types of power cables for your unique needs.

Turn-key Service for Your Power Lines under 500 kV

One- stop supply of all types power cable and its accessories and turn-key services of technical consulting, cable fabrication & installation and completion test for your power lines under 500kV.

Related Product

The manufacturing process for these power cables

Power cables having a very complex structure and requiring good insulation performance and mechanical strength to ensure the safety and reliability of power transmission in his whole service life. As the same time, it also have a very high requirement for the working staff, his profession to understand its main features of each type raw materials, and skills for all controls during the whole manufacturing process.

The production process of power cables is complex and precise, and the following are the main production steps we need to comply with :

- Selection and inspection to Raw materials

The main raw materials for fabrication power cables include copper or aluminum conductors, PVC, PE, XLPE or TR-XLPE insulation materials, sheath materials and other auxiliary materials. These raw materials need to TAKE a strict quality inspection to ensure compliance with production standards.

- Fabrication of the conductors

It is one of the key steps in the production of power cables. Copper conductors are usually made into uniformly sized wires through continuous casting, while aluminum conductors are produced using continuous drawing machine technology. In the process of conductor making, wire drawing and annealing are also required to improve the flexibility and conductivity of the conductor. For high-voltage power cables, the conductor is usually subjected to compression twisting or wire twisting technology to ensure the roundness of the conductor and reduce moisture infiltration.

- Fabrication of insulation materials

The production of insulation material is an extremely important during the whole process. At present, cross-linked polyethylene (XLPE) is the main material for insulation of high-voltage cables, and its production processes include catenary dry crosslinking (CCV) and tower type dry crosslinking (VCV). The extrusion of the insulation layer usually adopts a triple-extrusion process, which simultaneously extrudes the conductor shielding layer, insulation layer, and insulation shielding layer. This process can improve the concentricity and roundness of the insulation layer.

- Processing of buffer layer and shielding layer

High voltage cables usually have buffer and shielding layers outside the insulation layer. The buffer layer can use a semi conductive buffer water blocking layer to prevent moisture infiltration and withstand thermal expansion during operation. The shielding layer is made of semiconducting material and manufactured through extrusion process to ensure uniform distribution of electric field.

- Processing of metal sheath

Metal sheaths are usually made of continuous extruded corrugated aluminum tapes to improve the sealing and mechanical performance of cables. The processing of metal sheaths requires ensuring their compressive and bending resistance to meet the requirements of construction and operation.

- Production of outer sheath

The outer sheath is the outer layer of protection for power cables, usually made of PVC or PE material and manufactured through extrusion technology. The outer sheath not only needs to have wear-resistant and corrosion-resistant properties, but can also be made of flame-retardant or anti termite materials according to customer requests.

- Assembly and testing

The components such as conductors, insulation layers, shielding layers, and sheaths prepared through the above processes are assembled and formed according to the predetermined structure. After assembly, the cable needs to undergo strict testing, including electrical performance testing (such as volt ampere testing, insulation impedance measurement) and physical performance inspection (such as size, appearance, mechanical strength, etc.). Only products that pass the inspection can be packaged and shipped.

- Post processing

Some high-voltage cables also require post-treatment, such as coating with asphalt or graphite, to prevent corrosion of the metal sheath and extend the service life of the cable.

The production process of high-voltage cables is complex and requires extremely high precision. Each link needs to be strictly controlled to ensure the performance and reliability of the cables, meeting the high requirements of modern power systems for high-voltage cables.

- Packing & shipping for power cables.

After carried out all above-mentioned proccess, it is approved that the finished power cables are qualified & acceptable in quality; We will forward all these power cables into next step, packing to seal the drums or reels and arrange trucks or containers to ship the goods to where clients requested to deliver.