A Better Supplier of Thermocouple Wire Type J in China

ISO 9001 & 14001 Certificated Factory

Full Range of Thermocouple Wire Available

Pre-assemble with Your Required Temperature Sensors

What is a Thermocouple Wire Type J

Thermocouple Wire Type J is another category of the thermocouple wire, The conductive material of its positive wire is pure iron, and its negative wire is a copper nickel alloy, also called constantan. Its nominal chemical composition is 55% copper and 45% nickel, as well as some components of manganese, cobalt, and iron etc. Although it is called constantan, it is different from nickel chromium constantan and copper constantan, so it cannot be replaced by thermocouple Wire Type E and Thermocouple Wire Type T.

The coverage measurement temperature range of the Thermocouple Wire Type J is -200~1200 ℃, but the commonly used temperature range is 0~750 ℃. Thermocouple Wire Type J has the advantages of good linearity, high thermoelectric potential, high sensitivity, good stability and uniformity, and low price (iron conductor), and are widely used by worldwide users. Thermocouple Wire Type J can be used in vacuum, oxidation, reduction, and inert atmospheres, but the positive wire, iron oxidizes quickly at high temperatures, so its use temperature is limited and it cannot be directly used in sulfurization atmospheres at high temperatures without protection.

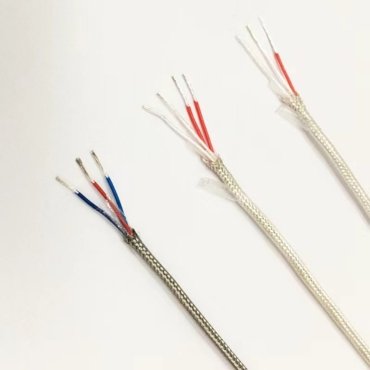

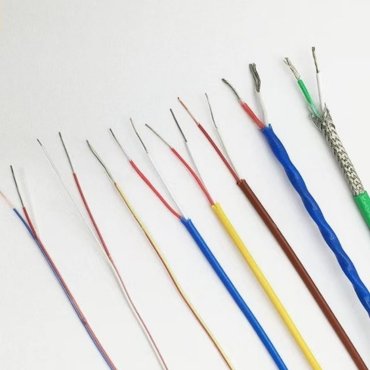

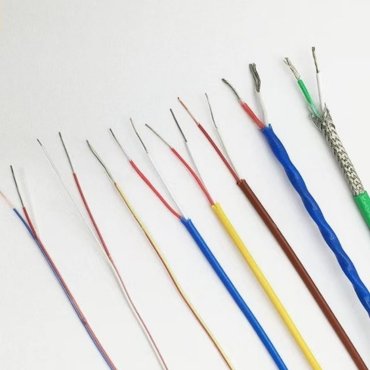

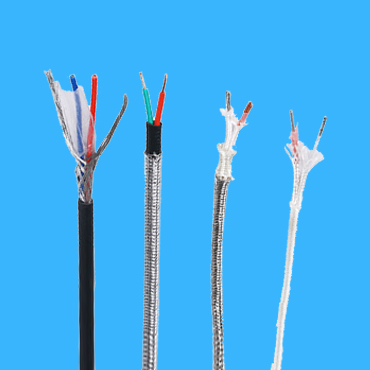

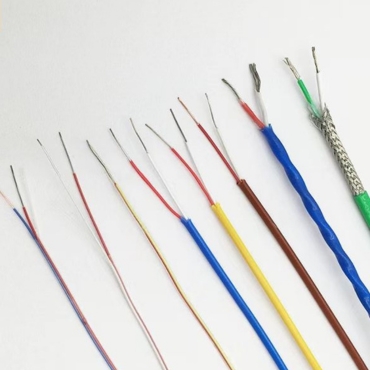

Thermocouple Wire Type J by its insulation & Sheath material

There are hundreds of types of Thermocouple Wire Type J available here, due to its different insulation & sheath material, and braiding or armoring layer.

Custom Fabrication of Thermocouple Wire Type J, Complying with Different Standards

Thermocouple Wire Type J is mostly cheap thermocouple wire, widely used in different industris; the full range of the wire is available here, compliance to the requirement of following standards,

ASTM E230 & ANSI MC 96.1; IEC 60584; BS 1843; DIN 43722; JIS C1610-1995; NF C 42-324

Related Product

How to Identify a Thermocouple Wire Type J & T

The method to distinguish between K-type thermocouple wires and thermocouple wire type J is to find a magnet. The positive pole of the K-type thermocouple wire is green and non-magnetic, while the negative pole is black gray and non-magnetic. The positive pole of the thermocouple wire type J is magnetic and the negative pole is non-magnetic; In practical use, as long as the temperature range is appropriate, there is no significant difference.

Second, A K-type J-type graduation table is placed in boiling water at 100 degrees Celsius to test its low voltage potential value. The data is recorded and compared with the graduation table. If the test data is close to the graduation table, it indicates that it is the one from the graduation table. If it is still not working, buy a temperature instrument with J-type graduation number and test the two sensors separately to obtain the result.

And also K-type is nickel chromium nickel silicon, with a usage temperature of 200 to 1300 degrees depending on the diameter of the wire, while thermocouple wire type J is iron constantan, with a usage temperature of -200 to 750 degrees depending on the diameter of the wire.

Thermocouple wire Type J VS. Type K

1. The usage environments of the two types thermocouple wire are different:

The usage environment of thermocouple wire type J : it can be used in vacuum, oxidation, reduction, and inert atmospheres, but the positive electrode iron oxidizes quickly at high temperatures, so the usage temperature is limited, and it cannot be directly used in sulfurization atmospheres at high temperatures without protection.

The usage environment of K-type thermocouple wire: K-type thermocouple is a temperature sensor, normally, it is used with other associated instruments, for displaying, recording and system regulator etc.

2. The characteristics of the two types of thermocouple wire are different:

Characteristics of thermocouple wire type J :

It has good linearity, high thermoelectric potential, high sensitivity, good stability and uniformity, and are inexpensive.

Characteristics of K-type thermocouple wire:

(1) Wide measurement range. Commonly used thermocouple wires can measure continuously from -50~+1600 ° C, while some special thermocouple wires can measure temperatures as low as -269 ° C (such as gold iron nickel chromium) and as high as+2800 ° C (such as tungsten rhenium).

(2) Simple construction and easy to use. Thermocouple wires are usually composed of two different types of metal wires, and are not limited by size or beginning. They have protective sleeves on the outside, making them very convenient to use.

(2) Simple construction and easy to use. Thermocouple wires are usually composed of two different types of metal wires, and are not limited by size or beginning. They have protective sleeves on the outside, making them very convenient to use.

3. Working temperature range is different

The working temperature of thermocouple wire type J : The coverage measurement temperature range of iron constantan thermocouple is -200~1200 ° C, but the commonly used temperature range is 0~750 ° C.

The working temperature of K-type thermocouple wire: When the operating temperature is between 1300~1800 ° C and high precision is required, B-type thermocouple wire is generally selected; The precision requirement is not high, and the atmosphere allows for the use of tungsten rhenium thermocouples. Generally, tungsten rhenium thermocouple wires are selected for temperatures above 1800 ° C; S-type thermocouple wires and N-type thermocouple wires are available for use at temperatures between 1000 and 1300 ° C, which require high accuracy; K-type thermocouple wires and N-type thermocouple wires are generally used below 1000 ° C, and E-type thermocouple wires are generally used below 400 ° C; At 250 ° C and negative temperature measurement, T-type thermocouple wires are generally used. At low temperatures, T-type thermocouple wires are stable and have high accuracy.

How to Judge the quality of a thermocouple wire type J

To determine the quality of a thermocouple wire type J, the following steps are required:

1) Check for any abnormal changes or damage to the wire appearance;

2) Conduct insulation testing to ensure that there is no short circuit or open circuit between the two conductors;

3) Verify the sensitivity and error range of the thermocouple using a standard temperature source;

4) Compare the deviation between the actual measurement value and the theoretical value according to the measurement range in the user manual, and determine whether the thermocouple wire has failed or needs to be adjusted.