A Reliable VFD Cable Manufacturer in China since 2010

Over 10 years manufacturing experience for CE & UL/CSA certificated VFD cable in China

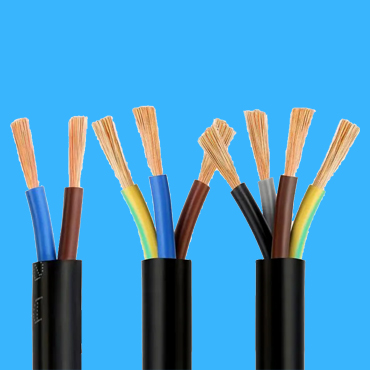

What is a VFD Cable

Variable Frequency Drive Cable, is known for VFD Cable; It is used to carry power from AC drive systems to AC motors and widely used in industries of automation, chemical, oil & gas, mining, marine & offshore.

PowerTel & its associated factory have capacities to provide you a wide range of VFD cables in various applications. Please contact our engineers for your custom need of this VFD Cable and we will give you a tailored design and fabrication of it.

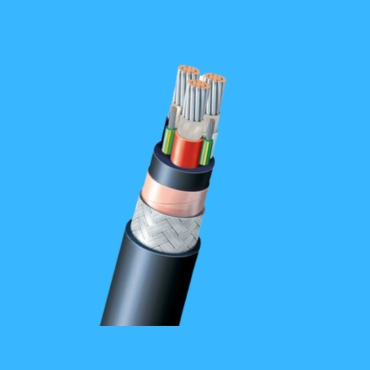

UL 2277 Certificated VFD Cable

This VFD cable is mainly used in high-power variable frequency drive systems in different industrial applications, and the interconnection between equipment and variable frequency motors having a certain degree of flexibility. only for the North American market where UL/CSA certified VFD cables are needed.

Low capacitance, excellent anti-electromagnetic interference performance

Product Feature Box

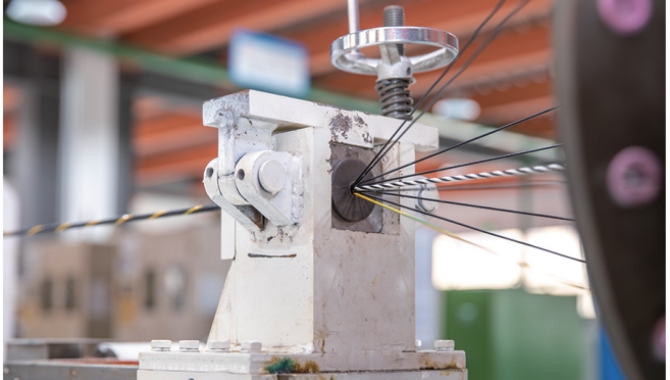

State-of-the-art Manufacturing Facilities

Continous investment on bringing in new manufacturing equipments for VFD cables, this would be a strong guaranttee of the highest qualit of our cables.

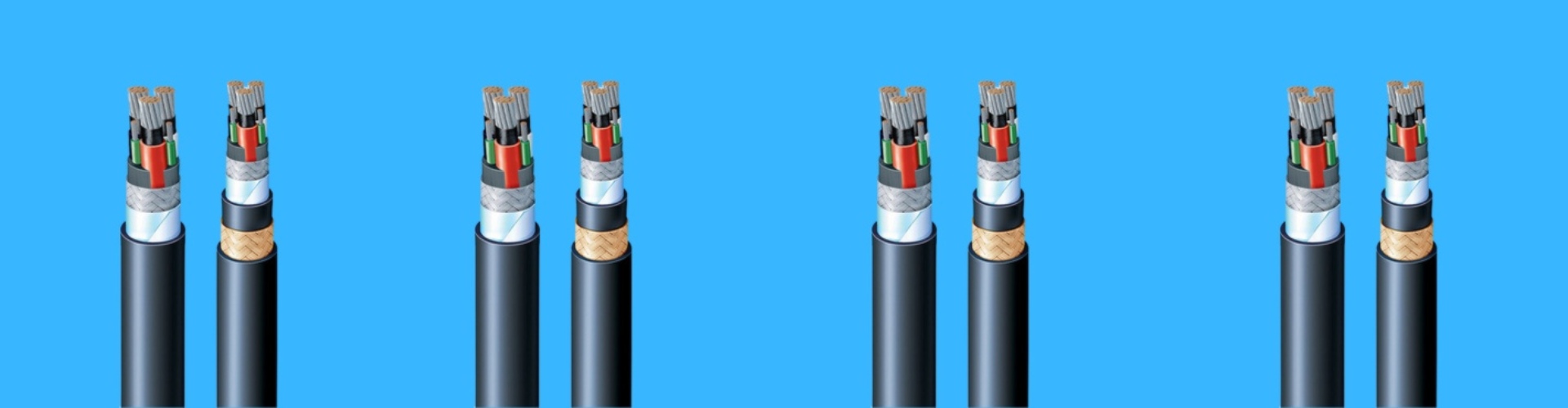

UL Certificated VFD Cable

Our VFD cables were certificated by UL 44, 1277 and 2277;

Fast Delivery Time for VFD Cable

Based on our large production capacity and some VFD cables in stock, plus our strong logistic system, a fast delivery time of these VFD cables were assured here.

Package Supply of VFD Cable and its Hardware

Except the supply of these VFD Cables, we are able to provide you cable connector and termination kits.

Related Product

What is a VFD cable, cable design and its functions?

According to the working principle of various frequency converters, VFD cables should focus on solving the following problems:

According to the working principle of various frequency converters, VFD cables should focus on solving the following problems:

(1) The cable body emits electromagnetic waves to the outside, suppressing the interference of higher-order harmonics through the cable to the outside.

To achieve effective suppression of high-frequency interference, the shielding structure of VFD cables is particularly important. The shielding structure is the best method to suppress external high-frequency interference, and the shielding structure is copper wire woven shielding.

(2) it solves the problem of anti-interference ability and insulation safety and reliability from the perspective of cable structure design.

The frequency regulation range of variable frequency power supply is wide. Therefore, to ensure cable safety, we should start from the following three aspects:

(1) Increase the insulation thickness, improve the insulation voltage resistance, and select materials with better insulation performance.

(2) Add a semi conductive layer outside the conductor to homogenize the electric field and reduce tip discharge.

(3) The VFD cable adopts a symmetrical structure to achieve uniform electric field and phase balance.

3.Shielding layer grounding measures

4. Additional tests for VFD cables

Generally, impulse voltage test is not required for low-voltage cables. For example, IEC 60502 standard only specifies impulse voltage test for cables of 3.6/6kV and above. The connection cable of the variable frequency motor is slightly different and needs to withstand high-frequency pulse voltage. The high-frequency wave amplitude can reach 1200~1900 V, and the ringing frequency is about 100~2000 kHz. Pulse voltage test (type test) is conducted on the cable to verify its insulation level. The test can refer to the IEC 60502 standard, which applies ten pulse voltage tests, positive and negative, and the test voltage can be considered as 40 kV.

Usage characteristics of VFD cables

1. The maximum allowable working temperature for cable conductors in the long term is 90 ℃.

2. During a short circuit (maximum duration not exceeding 5 seconds), the maximum temperature of the cable conductor shall not exceed 250 ℃.

3. The bending radius of wrapped shielded cable laying shall not be less than 15 times the outer diameter of the cable, and the bending radius of wrapped shielded cable laying shall not be less than 20 times the outer diameter of the cable.

Technical Characteristics of VFD Cables

1. Having small insulation medium loss and excellent thermal aging performance;

2. It has high resistance of voltage impulse, which can withstand the pulse voltage in a very speed of frequency conversion;

3. Has good shielding performance, with a shielding transmission impedance not exceeding 1 Ω/m within the range of 100MHz;

4. The cable structure is compact and round, with high electrical safety. The symmetrical three plus three cable structure design has more stable transmission performance than four core cables;

5. It can reduce the adverse effects of higher-order harmonics in the output of the frequency converter, reduce motor noise, and improve the torque efficiency of the motor;

6. It can improve the power factor of the motor input power supply and reduce its capacity;

7. Suppressed the increase in voltage at both ends of the capacitor caused by the instantaneous increase in power supply voltage, resulting in overvoltage protection for the frequency converter.

Development of 3.6/6-6/10 kV Medium VFD Cables

Due to the large-scale mechanical equipment, the motor capacity needs to be expanded, and the output current of the corresponding variable frequency power supply also needs to be increased. due to the limitations of high current variable frequency components, the development of further improving current capacity technology is limited. On the other hand, increasing the output voltage of the variable frequency power supply is relatively easy. At present, 3.6/6-6/10kV medium voltage VFD cables have been put into use. From the perspective of insulation structure and electrical, mechanical and physical properties, they can be equivalent to power cables. Cross linked polyethylene is obviously the preferred insulation material. If it is required to be flexible when laying, Ethylene propylene rubber insulation has certain advantages. Due to the increase in working voltage, the emission ability of high-frequency electromagnetic waves is significantly enhanced, so the shielding structure is required to be more complete. Under the working conditions of VFD cables, coaxial cables are a suitable structure, so three main cores of the VFD cable adopt a coaxial structure, and the overall shielding structure is the same as that of the low-voltage VFD cable.

If you need to have a quote of these VFD cables, please conact us at : info@powertel-solutions.com